January 1,2024.

Polyurethane Foam Sandwich Panels Application

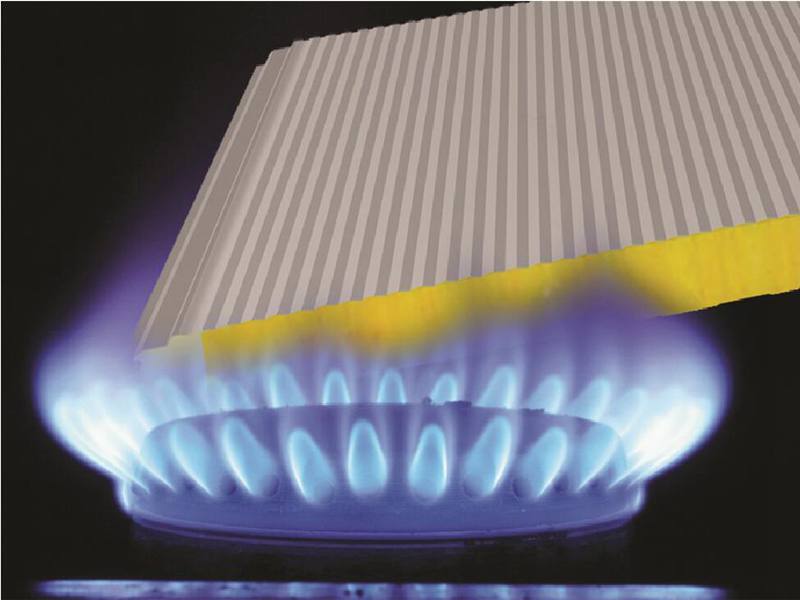

Polyurethane Foam Sandwich Panels Application: 1.Public buildings: Polyurethane foam sandwich panels are mainly used in roofing and facades of public buildings with large space requirements such as: Mechanisms, station waiting or waiting halls, stadiums, theaters and auditoriums, exhibition halls and exhibition centers, museums, etc. Public buildings due to need more space requirements, indoor air-conditioning, fire and a series of higher than the requirements of the industrial plant features such buildings use truss or truss truss structure, so the roofing material in Lightweight, heat and heat insulation, fire safety, waterproof, sound absorption, durability and other aspects have put forward higher requirements. Logistics park 2.Industrial plant, warehouse: Polyurethane sandwich panels are mainly used in industrial plants, warehouses and exterior walls. The past, the roof of industrial plants to use more precast concrete or asbestos. With the rapid promotion of light steel structure, polyurethane sandwich panels also replaced the above two kinds of materials with a number of significant advantages. While providing better insulation effect, the sandwich panel cooperates with the mature and developed light steel structure, which can truly reflect the light weight, high efficiency and flexibility of the light steel system and a series of advantages such as flexible arrangement. Therefore, it has become Preferred solution. For multi-storey industrial plants, in addition to the roof of the roof can be used sandwich panels, the outer wall can also be used for flexible polyurethane sandwich panels layout, through the colorful changing colors and shapes to achieve the purpose of beautifying the building's appearance. For industrial buildings with constant temperature and humidity requirements, the use of sandwich panels with better thermal performance than brick walls can greatly save the operating costs after completion. Steel structure factories 3.Purification project: With the continuous social progress, the rapid development of electronics and pharmaceutical industries, in these industries manufacturing process, we need to provide clean production environment. Color coated sandwich panels because the surface of the color coated with dust is not easy to attach, easy to clean and seams less, so the sandwich panels as interior walls and ceiling materials, are widely used in clean requirements of the production and working environment. Applications include electronics and computer products manufacturing, medical supplies and pharmaceutical production, aerospace, precision instrumentation, food production, medical operating room and other industries. Although some factories do not require high degree of cleanliness, but in view of the characteristics of flexible disassembly sandwich panels, but also extensive use of polyurethane sandwich panels as the internal walls of the plant. Purification workshop 4.Combination of houses: Polyurethane foam san...

View More