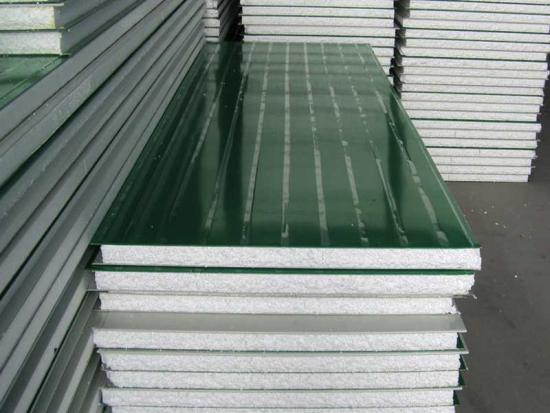

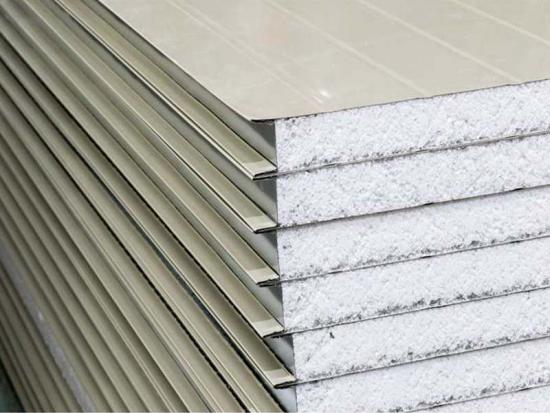

A sandwich panel is one structure made of three layers of material: low density core inserted material in between two relatively thin steel skin layers. This sandwich setup allows to achieve excellent mechanical performance at minimal weight. The very high rigidity of a sandwich panel is achieved thanks to interaction of its components under flexural load applied to the panel: core takes the shear loads and creates a distance between the skins which take the in-plane stresses, one skin in tension, the other in compression. General information on sandwich panel structure, different sandwich core types available and the potential with respect to weight savings is available in the following reference.

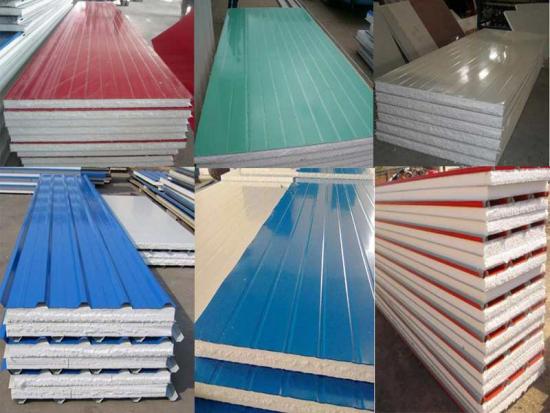

Size Details as below

Cover width : 950mm 1150mm for wall, 950mm for roof

Steel thickness: we can do from 0.3mm-0.6mm

Steel color: white ,see blue or as your inquiry

Interlayer thickness: 50mm ,75mm, 100mm ,150mm

EPS density: from 8kg/m3 to 20kg/m3

Length: less than 11.8meter

Delivery time:5-10days

Quality:accept your inspection or MIC certificate.

How we do business

Step1. Control the raw material

Our factory is steel building materials manufacturer over 25 years production experiences, we have good reputation raw material suppliers in China and cooperate well, like BAO Steel, Blue Scope, Yehui, etc

As different clients require different level goods, except those high level suppliers, we also have some middle level suppliers with competitive price, with years experiences, our purchase dept manager will visit our material suppliers regularly to make sure they function well, the most important thing is we get the right material to do production for each client on time!

Step 2. Control the roll forming (our production)

After 25 years production experiences, we now have a complete set of workflow.

Confirming detail specification with clients → Purchase material →

→ Inspect the quality first before sending to our factory → EPS Sandwich Panel Roll Forming →

→ inspect the finished sandwich panel → packing waiting for delivery

We also accept customer or third party inspection before shippment.

We now have 4 EPS sandwich panel production line, meantime, we maintain our each lines regularly, to produce the sandwich panel perfectly.

Features

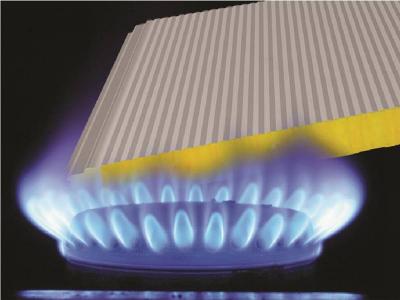

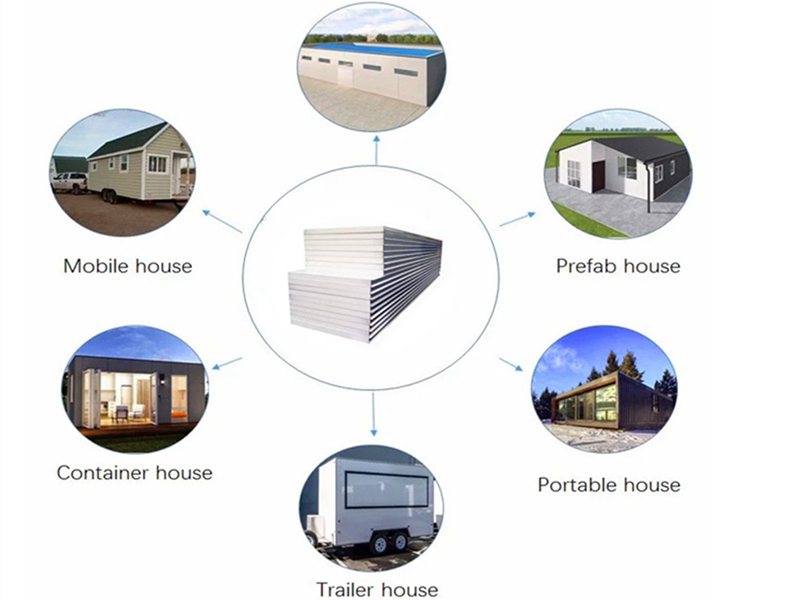

1. Heat and sound insulation. Temperature suitable for eps sandwich panel ranges from -200 centigrade to 150 centigrade.

2. Waterproof, anti-corrosion, good chemical resistance, insect-free etc.

3.Advanced Tech: Automatic Italian rolling machines make the whole process of manufacture effective.

4.Energy conservation, environmental protection, economical, heat insulating, good structure, easy construction.

5. Light weight enough to reduce building expense.

6.Time can be saved on a building project due to the simple installation.

Service&Support:

We are one combination of industry and trade company, and very professional with steel structure products in China. Because of good quality and service, competitive price, our products are sold worldwide, such as America, South America, Europe, Southeast Asia, Africa etc.

1)Professional sales team,One-to-one service;

2)Combination of industry and trade company,to ensure the service and price;

3)Experienced engineer team to offer professional technology service;

4)Intimate after-sales service.

Experienced technology suport, competitive price, professional service, we are here to help you go on with your project smoothly.