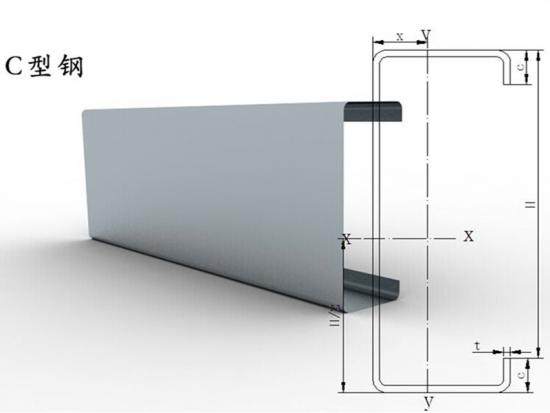

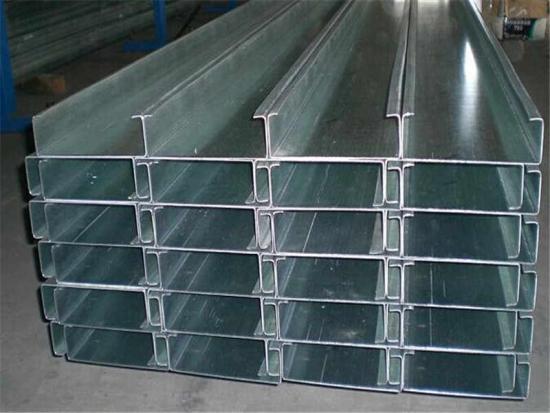

C channel is made of galvanized steel strips by the method of cold-bending

formed.The surface treatment are galvanized or bare. It has many advantages compared

with traditional structural steel, such as light weight, excellent performance cross-section, high-strength and so on.

Advantages

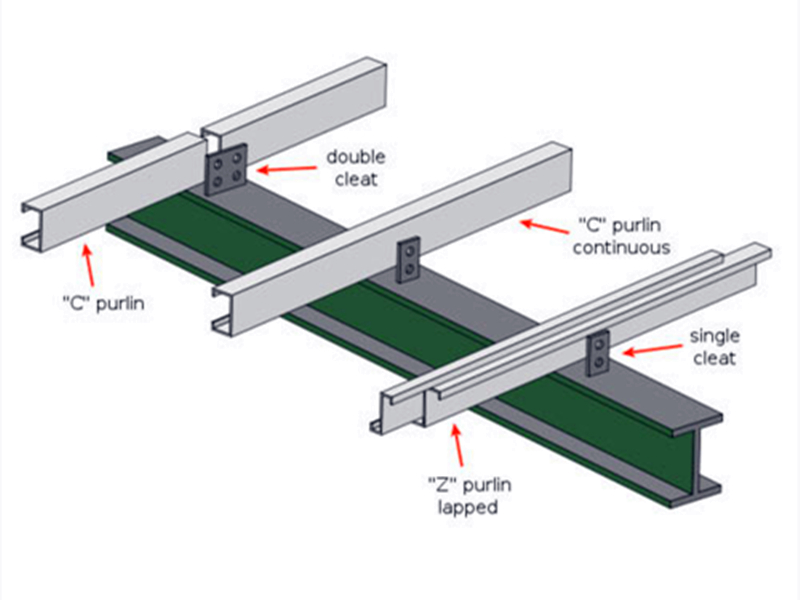

Ability to span length

Purlin erection is easier than others

Fast to erect and easy handling

No side drilling/cutting required

Assured dimensions and straightness

High durability, versatility and uniform quality

Low transportation cost due to decreased weight

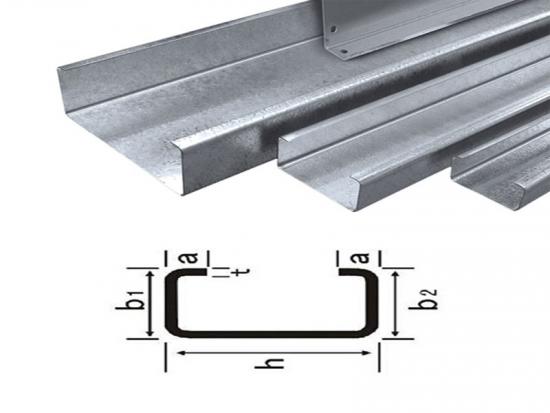

Product specs of C section frames:

|

Product name |

Building Material C Purlin High-Strength Galvanized Steel Purlin |

|

Shape |

C chanel |

|

Grade |

Q195,Q235,Q345 |

|

Zinc coating |

40-275g or as client's requirement |

|

Length |

20'GP:no more than 5.8 meter/pcs |

|

Thickness |

1.8-3.0mm |

|

Size |

100×50×50×20 ; 120×50×50×20 ;140×50×50×20 ; 160×60×60×20 |

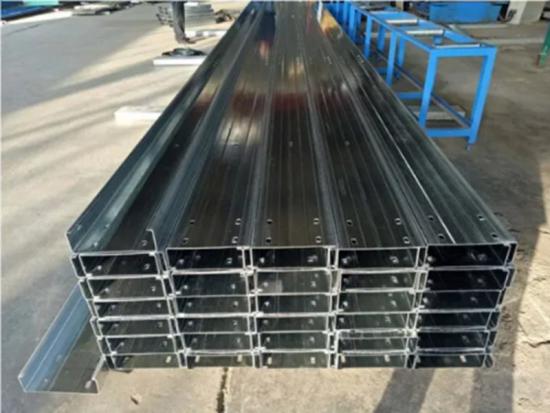

C purlins processing

C purlin production process has three stages,material preparation and equipment preparation and processing.

Material preparation:The related specs of GI steel strips will be prepared and loaded on equipment;

Equipment preparation:Our workshop manager will check and adjust the equipment to make sure the C steel purlin equipment is in correct status for production;

Processing:This is including holes pre-punching,cold rolled,cutting as per required length,and stack in proper position and well protected,then finally quality inspection by our QC people.