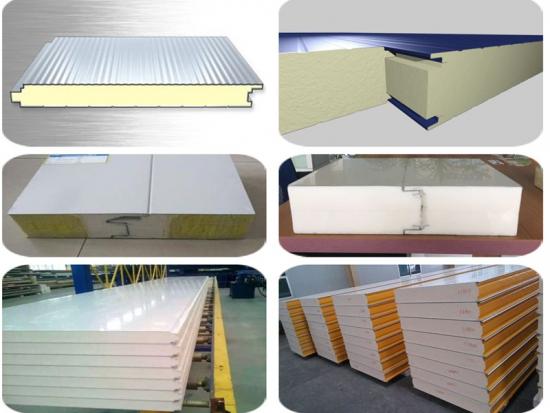

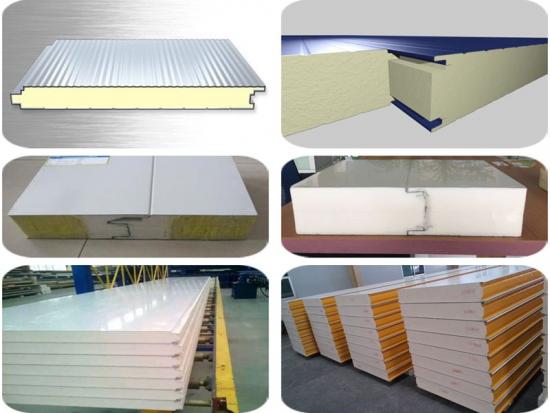

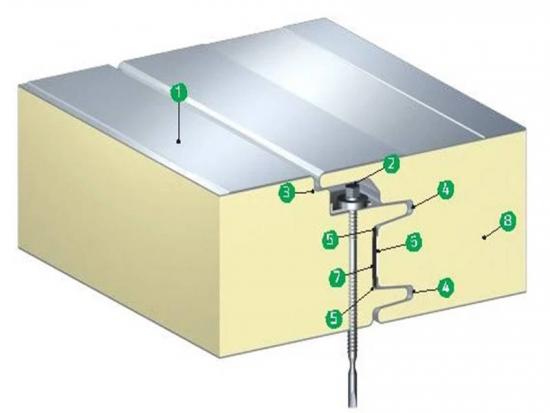

A sandwich panel is one structure made of three layers of material: low density core inserted material in between two relatively thin steel skin layers. This sandwich setup allows to achieve excellent mechanical performance at minimal weight. The very high rigidity of a sandwich panel is achieved thanks to interaction of its components under flexural load applied to the panel: core takes the shear loads and creates a distance between the skins which take the in-plane stresses, one skin in tension, the other in compression. General information on sandwich panel structure, different sandwich core types available and the potential with respect to weight savings is available in the following reference.

1)Suface sheet:

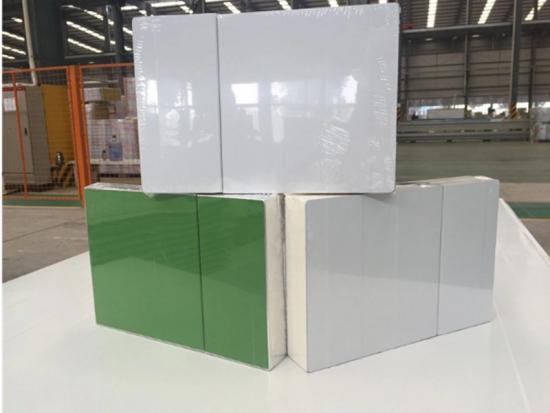

Usually the surface sheet of PUR or PIR sandwich panels is PPGI or PPGL steel color coated sheets.PPGI is prepainted galvanized coated steel and PPGL is prepainted Al-Zn coated steel.For coating type,you could choose PE, PVDF, HDP, SMP,ect.Our strategic cooperation brands are Bluescope, Bao-steel, Shougang steel, Guanzhou steel, Yieh Phui steel,Xinyu steel,etc.

2)Polyurethane core material:

Our polyurethane core material strategic cooperation brands are D·BASF, Huntsman, WANHUA, etc.

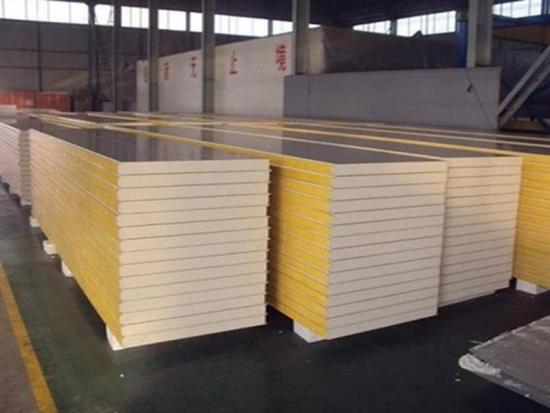

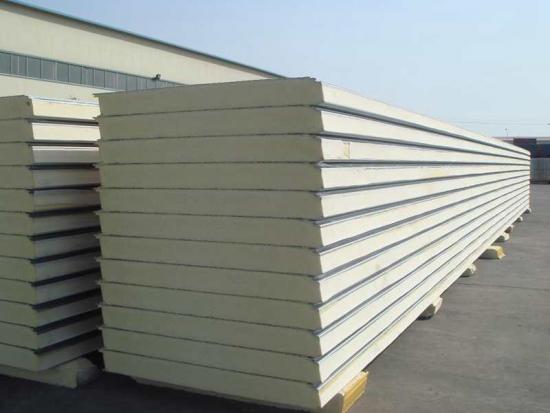

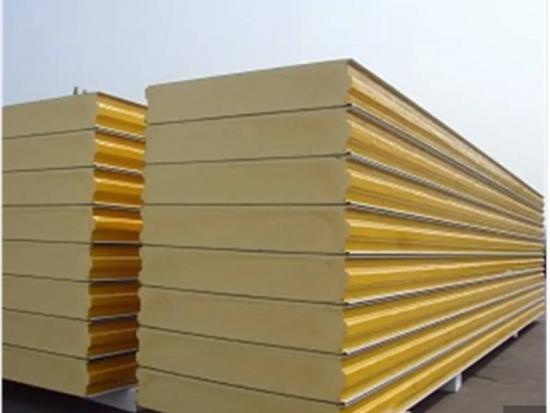

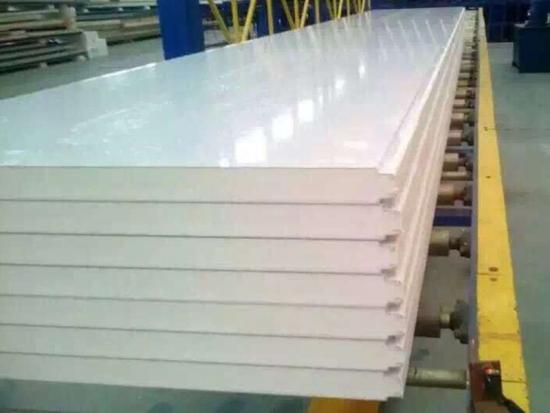

Polyurethane Sandwich Panel also called PU Sandwich Panel,the top & bottom sheet of this panel is Galvanized & Pre-painted steel sheets,and core material is 5 components Polyurethane glue, it is formed by heating, foaming & laminating. Polyurethane is the best material for heat and sound insulation. It can reduce the heat transmission caused by difference in the internal and external temperature, and get to maximum efficiency of freezing and refrigeration systems. It is a new type of heat insulation material for lower construction cost.Panels are in multiple varieties and specifications to meet the need of various sites and projects.

Size Details as below

Cover width : 1000mm/1120mm for wall, 1000mm for roof

Steel thickness: we can do from 0.4mm-0.6mm

Steel color: white ,see blue or as your inquiry

Interlayer thickness: 35mm, 40mm,50mm ,75mm, 100mm ,120mm,150mm

EPS density: from 40kg/m3 to 45kg/m3

Length: less than 11.8meter

Delivery time:10-20days

Quality:accept your inspection or MIC certificate.

Features

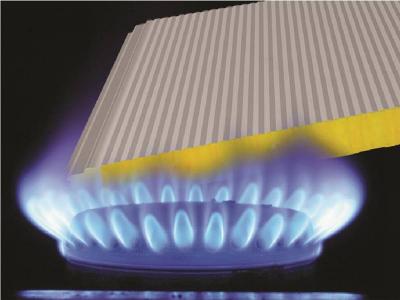

1. Good fireproof and flame-retardant performance. After adding flame retardant, PU board is a kind of refractory self-extinguishing material. It can effectively prevent fire spread while meeting fire, especially after a system of fire prevention treatment ,it can be sealed to form a non-flammable product.

2. Excellent Waterproof performance. PU sandwich board has the advantage of low water absorption rate,good water vapor permeability resistance, independent state of foam pores.mutual non-communication,closed cell rate of more than 90%, dense structure of micro porous foam material, more compact surface in contact with air,less water permeability and belonging to hydrophobic material.

3. Good weather resistance. Ability to withstand the most severe local climate and its changes, whether high temperature or cold climate, polyurethane PU board will not cause damage or deformation of exterior wall insulation system. Polyurethane PU plate reduces the strength and difficulty of the project, saves the project cost and construction time.

Service&Support:

We are one combination of industry and trade company, and very professional with steel structure products in China. Because of good quality and service, competitive price, our products are sold worldwide, such as America, South America, Europe, Southeast Asia, Africa etc.

1)Professional sales team,One-to-one service;

2)Combination of industry and trade company,to ensure the service and price;

3)Experienced engineer team to offer professional technology service;

4)Intimate after-sales service.

Experienced technology suport, competitive price, professional service, we are here to help you go on with your project smoothly.