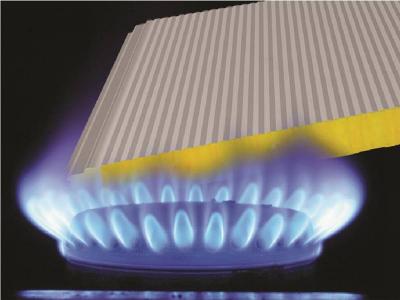

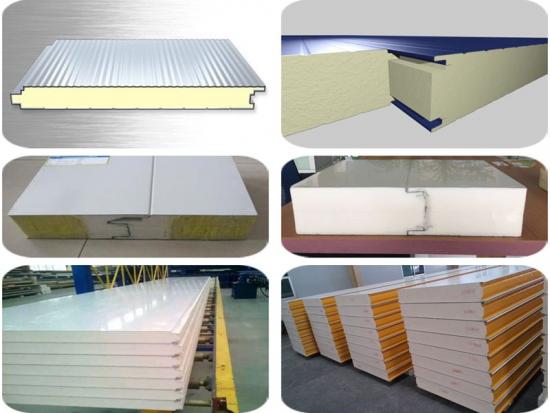

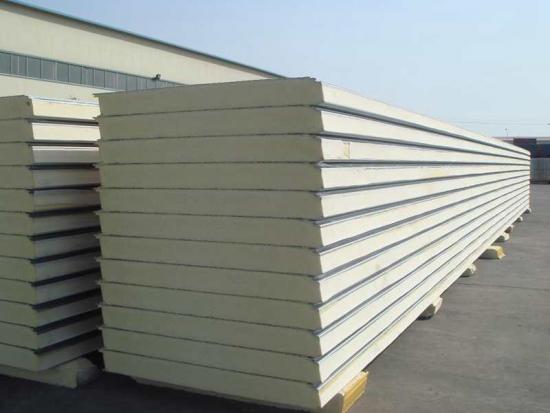

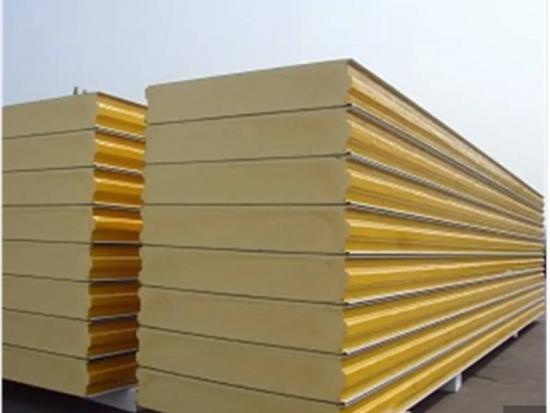

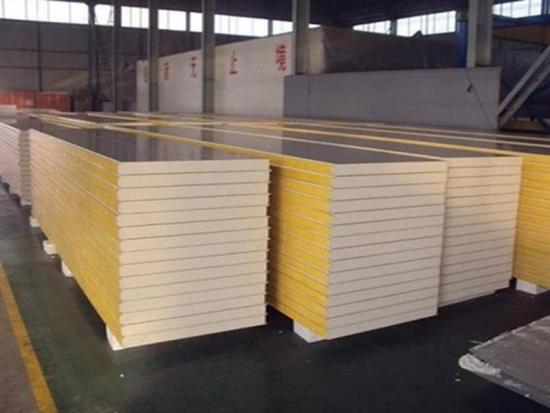

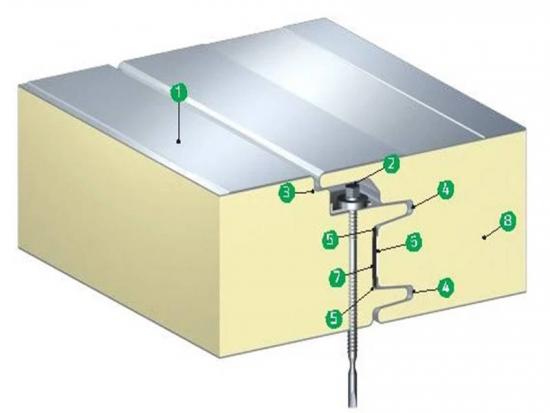

A sandwich panel is one structure made of three layers of material: low density core inserted material in between two relatively thin steel skin layers. This sandwich setup allows to achieve excellent mechanical performance at minimal weight. The very high rigidity of a sandwich panel is achieved thanks to interaction of its components under flexural load applied to the panel: core takes the shear loads and creates a distance between the skins which take the in-plane stresses, one skin in tension, the other in compression. General information on sandwich panel structure, different sandwich core types available and the potential with respect to weight savings is available in the following reference.

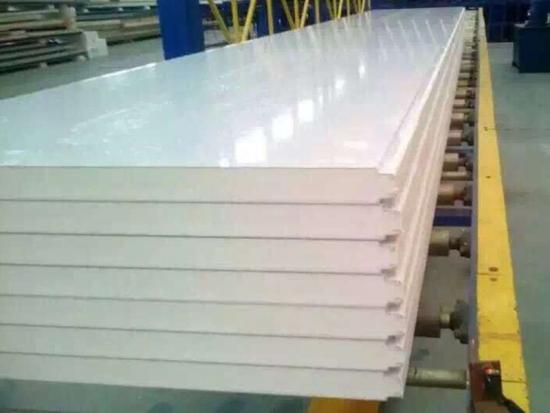

Size Details as below

Cover width : 1000mm/1120mm for wall, 1000mm for roof

Steel thickness: we can do from 0.4mm-0.6mm

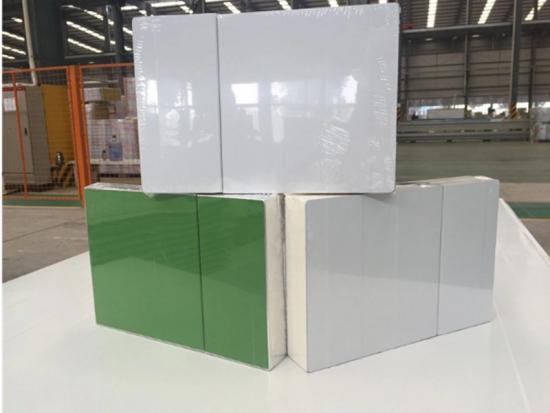

Steel color: white ,see blue or as your inquiry

Interlayer thickness: 35mm, 40mm,50mm ,75mm, 100mm ,120mm,150mm

EPS density: from 40kg/m3 to 45kg/m3

Length: less than 11.8meter

Delivery time:10-20days

Quality:accept your inspection or MIC certificate.

Our production line:

Our products packing/loading photos:

Our whole process control:

Service&Support:

Service&Support:

We are one combination of industry and trade company, and very professional with steel structure products in China. Because of good quality and service, competitive price, our products are sold worldwide, such as America, South America, Europe, Southeast Asia, Africa etc.

1)Professional sales team,One-to-one service;

2)Combination of industry and trade company,to ensure the service and price;

3)Experienced engineer team to offer professional technology service;

4)Intimate after-sales service.

Experienced technology suport, competitive price, professional service, we are here to help you go on with your project smoothly.