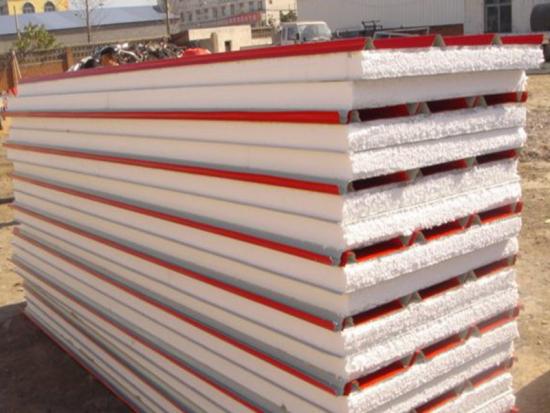

A sandwich panel is one structure made of three layers of material: low density core inserted material in between two relatively thin steel skin layers. This sandwich setup allows to achieve excellent mechanical performance at minimal weight. The very high rigidity of a sandwich panel is achieved thanks to interaction of its components under flexural load applied to the panel: core takes the shear loads and creates a distance between the skins which take the in-plane stresses, one skin in tension, the other in compression. General information on sandwich panel structure, different sandwich core types available and the potential with respect to weight savings is available in the following reference.

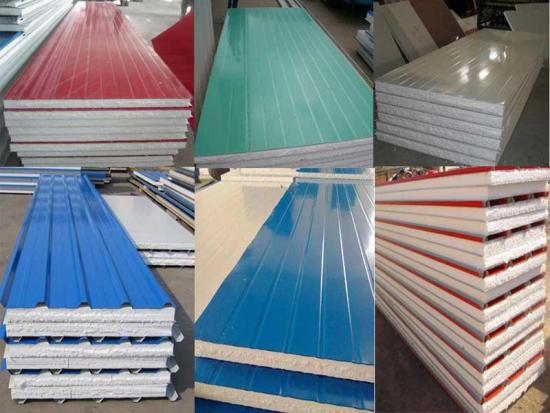

Features of EPS sandwich panel:

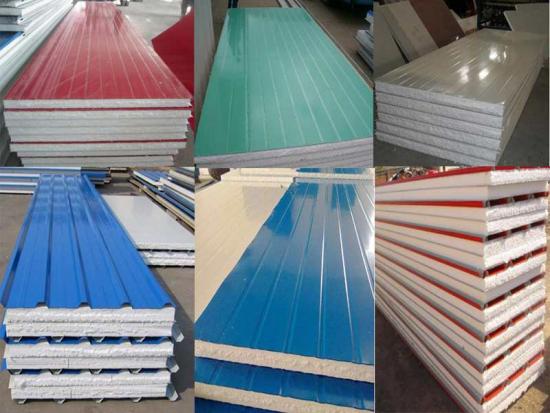

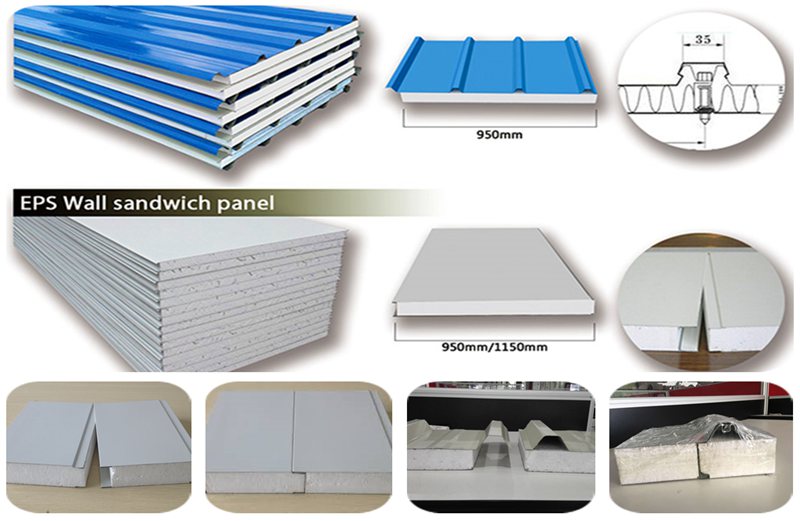

EPS sandwich panels with expanded polystyrene core are the most economical solution for roofs, outside and inside walls. The right profile of panels provides tightness and stiffness, the polystyrene core placement system on the panel connection makes using of additional sealants unnecessary, which greatly accelerates the installation of the panels and makes it easier. The core enclosed in galvanised and polyester coated steel sheet cladding provides good insulation. Global Star wall panels are used as an economical, easy to install and safe cladding for walls and roofs of halls, warehouses, large stores, garages, containers, cold rooms, pavilions, agricultural buildings, such as barns, piggeries, chicken coops, sheds, storage of vegetables and fruits.

|

Effective width |

wall panel: 950mm 1150mm roof panel: 950mm |

|

Length |

customized |

|

Materials |

eps+color steel sheet |

|

Thickness |

steel sheet: 0.3-0.7mm eps thickness: 50mm 75mm 100mm 150mm 200mm |

|

EPS density |

8-25kg/m3 |

|

Character |

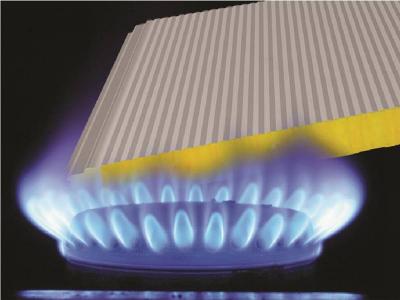

light weight, heat insulation, water resistant, easy installation |

|

Usage |

roof and wall panel for factory buildings, storages, warehouse, exhibition halls, gymnasiums |

Applications

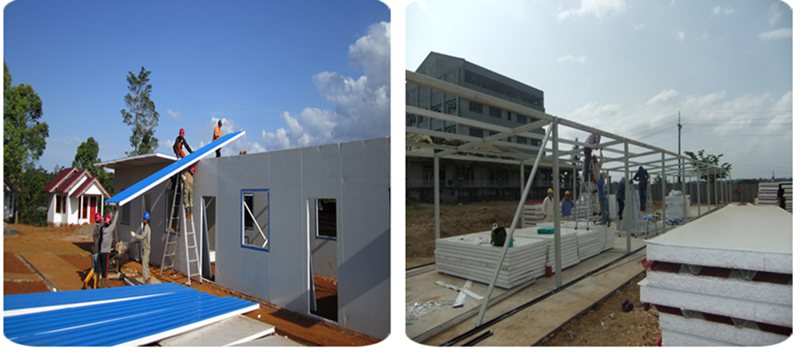

1) sandwich panel used in large industrial plants, warehouses, supermarkets, hospitals, stadiums, cold storage, activities room, buildings plus layer, clean workshop and heat insulation fire place.

2) sandwich plate appearance, bright color, good overall effect, it sets the bearing, thermal insulation, fireproof, waterproof in one, and no two decoration, is a widely used, especially in the construction site of the temporary facilities such as office, warehouse, walls, but also embodies the modern construction site civilization construction,

3) in the fast installation and put into use, the assembly and disassembly, material turnover multiplexing index, have obvious advantages, greatly reducing the construction site temporary facilities, will be indispensable new lightweight construction materials