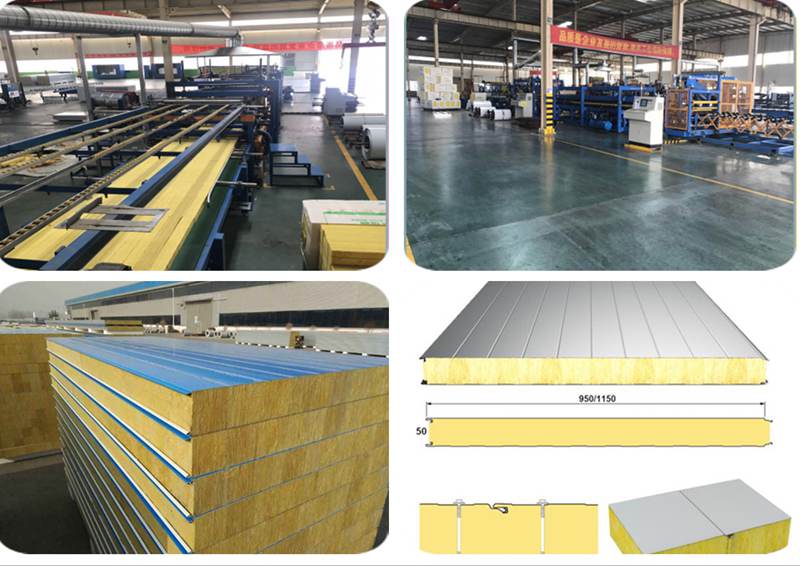

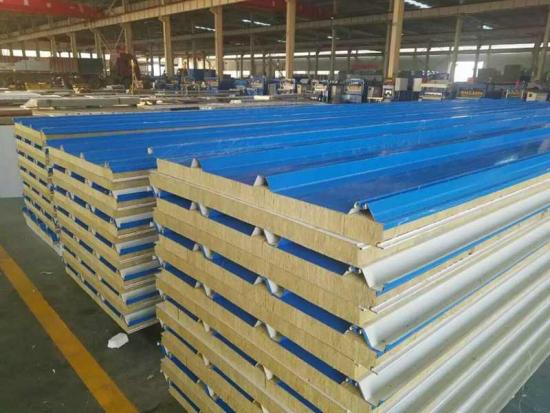

Rockwool sandwich panel and its manufacturing process is one the most advanced inventions, which in the factory automation equipment, rock wool and steel into a whole, thus changing the way of the rock wool plate before the compound required site , under the premise that meet the requirements of the building thermal insulation, sound insulation, fire protection, to achieve a high quality, efficient, reliable, safe target.

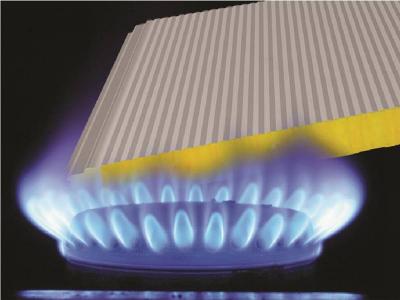

In order to meet customers' requirements,Australian rock wool sandwich panels is our newly developed sandwich panels,which is combined by rock wool as core material and two steel sheets on up and down side.Compare to other kind of sandwich panels,the most outstanding features of rock wool insulated panels is fireproof level,which is A1 level.

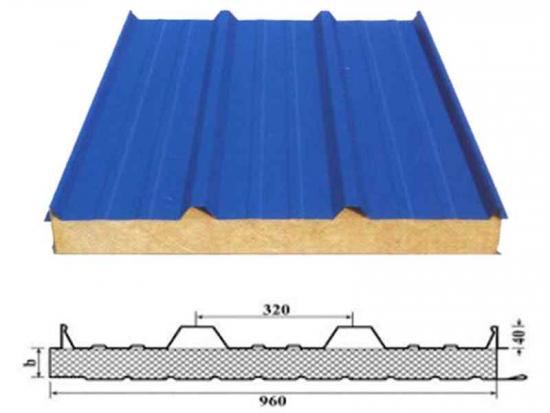

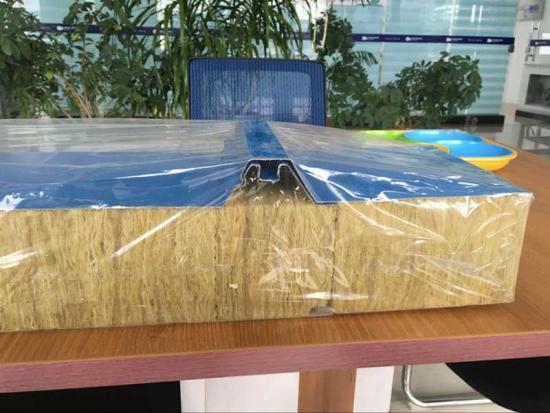

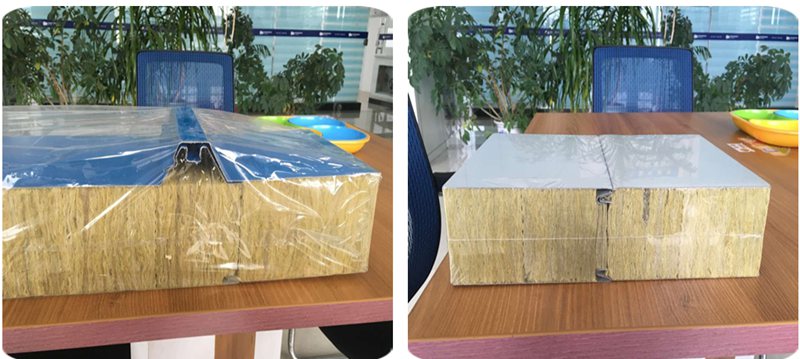

Hiden screw type joint way for roof sandwih panels;

Z lock joint way for wall sandwih panels;

Size Details as below

Cover wide:950mm/1150mm for wall, 950mm for roof

Length: Customized but less than 11.85meter usually.

Max 5.8m for 20GP container; Max 11.8m for 40GP/HQ container

Up color steel board thickness: 0.3mm to 0.7mm

Low color steel board thickness: 0.3mm to 0.7mm

Total thickness: 50mm,75mm,100mm,120mm, 150mm,

Coated materials: Zinc or aluminum alloy, 90-120G/M2

Fillings: rock wool

Steel Grade: Q235

Temperature Endurance: 800ºC

Water Absorption:≤2%

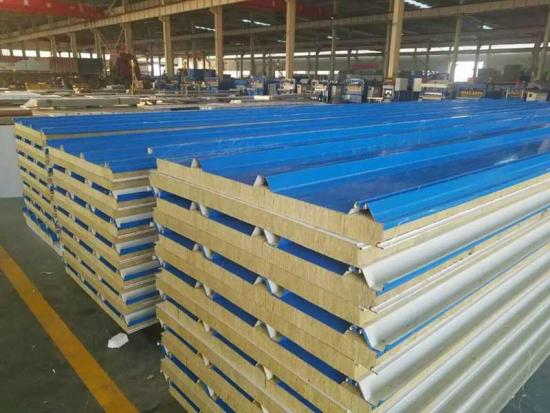

Steel color: white, Blue or RAL color

Our regular color is White grey,sliver grey,white silver grey,iron grey,dark grey,sea blue.

Applications

The sandwich panels can be used in large industrial plants,warehouses,supermarkets, hospitals, stadiums, cold storage, activities room, buildings plus layer, clean workshop and heat insulation fire place. Commercial housings in the cities, such as exhibition halls, shopping centers, offices and other housings for exhibition and sports.The temporary facilities in the construction site, such as office, warehouse.