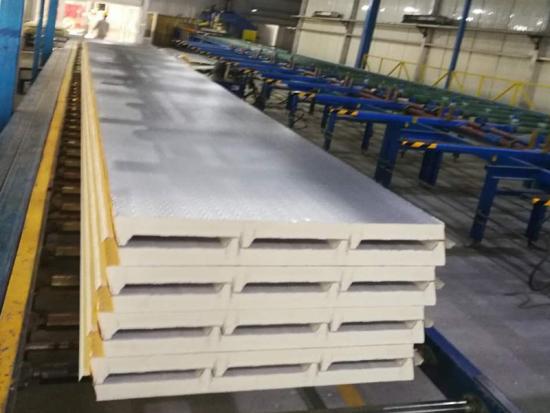

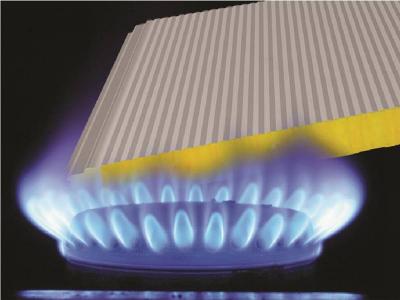

Polyurethane Sandwich Panel also called PU Sandwich Panel,the top & bottom sheet of this panel is Galvanized & Pre-painted steel sheets,and core material is 5 components Polyurethane glue, it is formed by heating, foaming & laminating. Polyurethane is the best material for heat and sound insulation. It can reduce the heat transmission caused by difference in the internal and external temperature, and get to maximum efficiency of freezing and refrigeration systems. It is a new type of heat insulation material for lower construction cost.Panels are in multiple varieties and specifications to meet the need of various sites and projects.

Material instruction:

1)Suface sheet:

Usually the surface sheet of PUR or PIR sandwich panels is PPGI or PPGL steel color coated sheets.PPGI is prepainted galvanized coated steel and PPGL is prepainted Al-Zn coated steel.For coating type,you could choose PE, PVDF, HDP, SMP,ect.Our strategic cooperation brands are Bluescope, Bao-steel, Shougang steel, Guanzhou steel, Yieh Phui steel,Xinyu steel,etc.

|

PUR/PIR Sandwich Panel Technology Data

2)Polyurethane core material:Our polyurethane core material strategic cooperation brands are D·BASF, Huntsman, WANHUA, etc.

|

|

| Density | 40-45kg/m3 |

| Thermal conductivity | 0.019-0.023W/M.K |

| Moisture permeability coefficient | ≤3.34Ng/Pa/m.s |

| Water absorption | ≤0.5g/100cm2 |

| Enclosed rate | ≥97% |

| The compression strength | ≥220KPa |

| The bending strength | ≥2450KN/m2 |

| Oxygen index | ≥28 |

| Fire proof | B1 |

| Dimensional stability | ≤1% |

| Application temperature | -50ºC-150ºC |

| Exterior Steel thickness | 0.4-0.7mm |

| Interior steel thickness | 0.4-0.7mm |

| Core material thickness | 40/50/60/75/100/120/150/200mm |

| Length | Less than 11.8m |

| Effective width | Wall panel:400-1120mm;Roof panel:1000mm |

| Grace finish | Embossment,small wave,big rib,flat finish |

| USAGE | Roof and Wall |

| Advantage | Heat Insulation, light weight, quick installation,waterproof, fireproof, soundproof, energy-saving,environmental friendly |