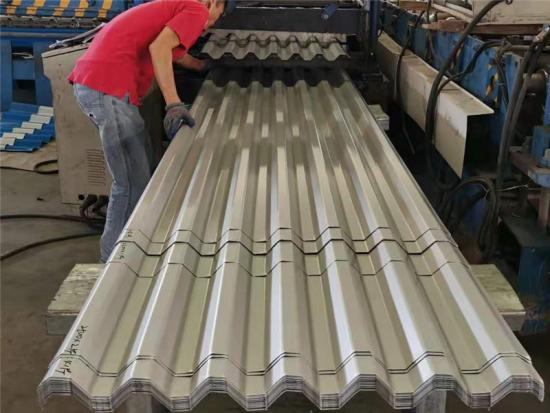

Steel roofing sheet is made from galvanized or pre-painted corrugated steel sheet.

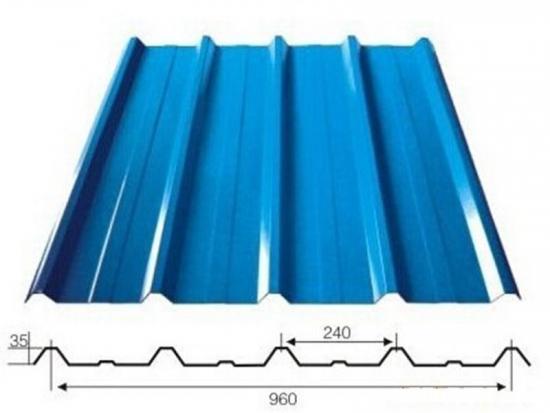

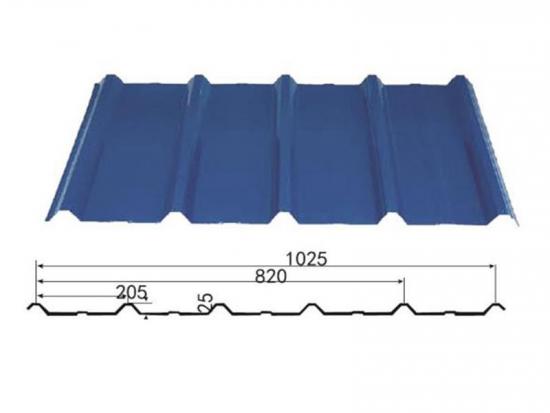

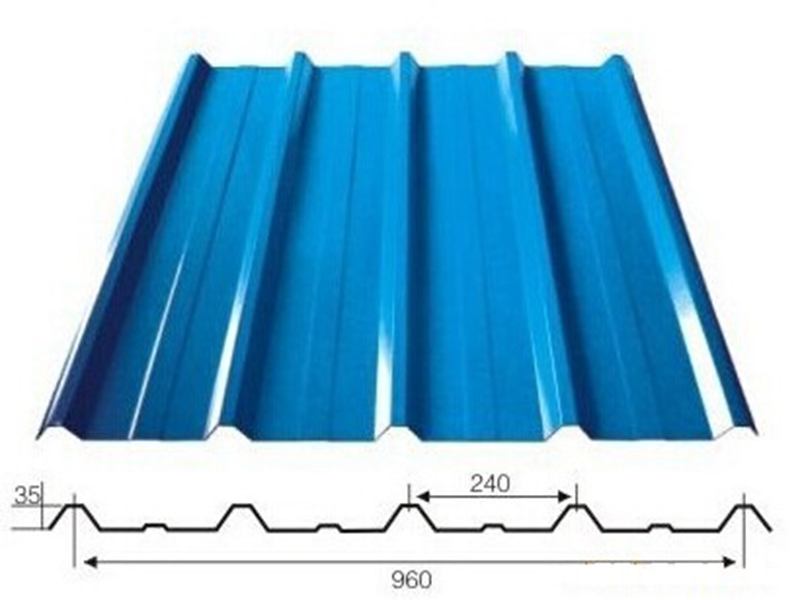

It is a component of the building envelope. Steel roofing can be used for residential and commercial buildings. YX35-240-960 has good effect on roof ceiling/wall and quick installation, only screws to fix on purlin.

Used color-coated steel plate, by roll cold-formed into a variety of wave pressure plate. It is suitable for roof, walls and interior and exterior decoration on industrial, civil buildings, warehouse, special construction and large span steel structure housing. With characteristic of lightweight , high strength, convenient construction, shockproof, fireproof, rain, long life, maintenance-free etc., now is been widely used.

|

Thickness: |

0.2mm-0.7mm |

|

Length: |

1800mm;2000mm;3000mm;4000mm;5000mm,2M,2.5M,3M,4M,4.5M,5M,5.8,6M,11.8M,as customer requirements. |

|

Width: |

960mm |

|

Surface Treatment: |

galvanized,corrugated,bright finished,chromated,oiled(or unoiled) |

|

Wave Design |

As customer requirement |

|

Technology: |

Cold rolled |

|

Life Period: |

15-20 years |

|

Package: |

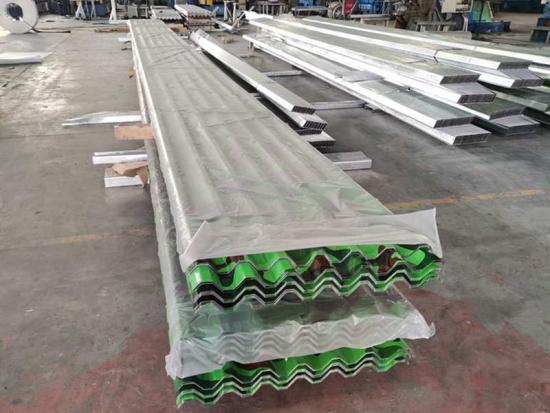

PVC foil |

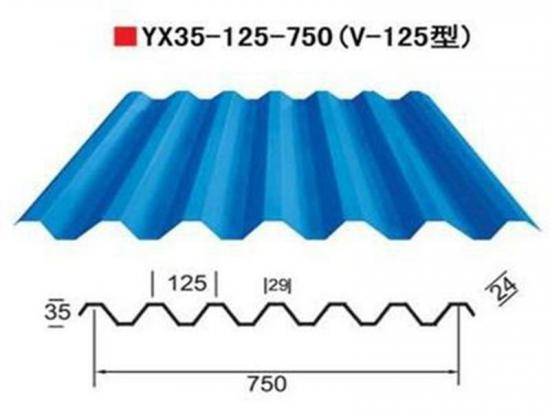

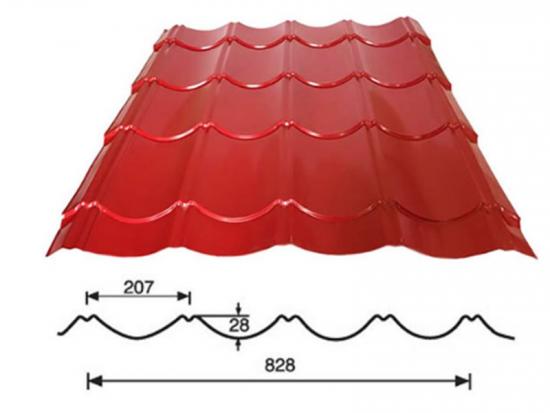

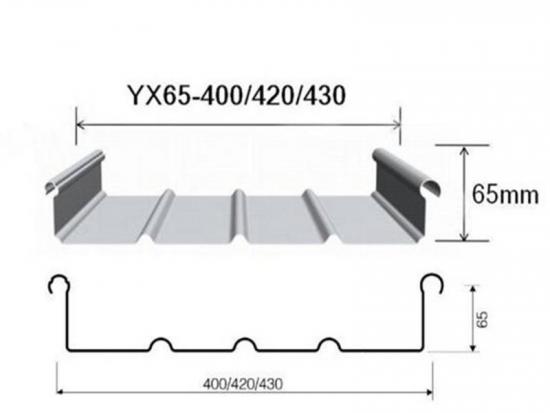

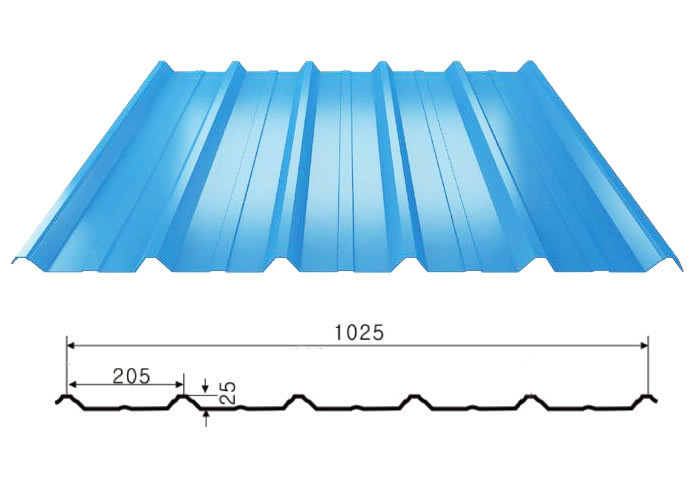

We can also supply many other types of roof sheet, such as below:

Package: PVC foil

Characteristic:

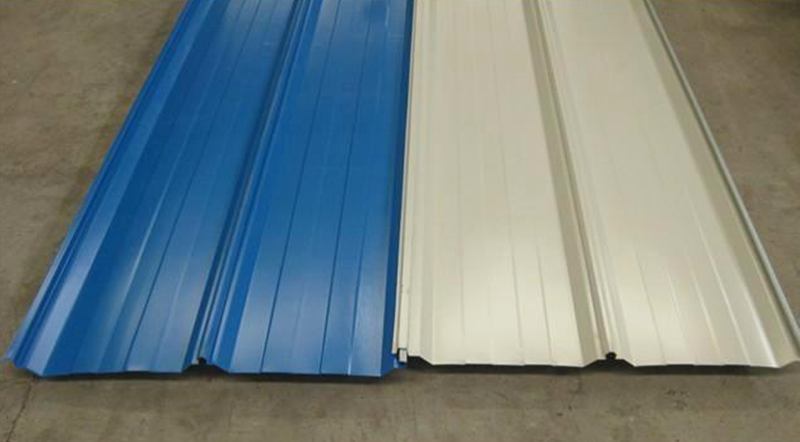

(1) Attractive and beautiful appearance, rich colors be chosen, combination flexible, can be expressed in different architectural styles.

(2) Lightweight(6~10kg/m2) and high strength(yield strength250~550MPa), with excellent features of waterproof, shockproof.

(3)Convenient construction and installation, reduce installation, transportation workload, shorten the construction period.

(4)Raw material steel sheet is part of green building material, recyclable.

Application:

Widely used in power plants, factories, warehouse, office, airport terminals, railway stations, stadiums, supermarkets, logistic centers and other steel structure constructions.

How to install the sheet metal roofing?

1.)Attach the roofer's harness to a secure point as directed by the manufacturer. Wear your safety goggles to protect your eyes from stray and other debris.

2.)Inspect the roof decking or rafters to make sure there are no screws, nails or other protrusion that might cause damage to the insulation. If there are, remove them. If there is any debris on the roof decking, sweep it off before starting.

3.)Unroll the insulation, starting at one corner of the building, vapor barrier side down. The first area to be insulated is the section of roof along the eaves, so that each subsequent row toward the peak lies on top of the previous row. This helps minimizes the chance of moisture getting between the rows of insulation if the roof spring a leak.

4.)Nail the edge of the insulation securely to the roof, using galvanized roofing nails. Space the nails about a foot apart along the edge.

5.)Move to a position about 4 feet from the first row of nails. Pull the insulation tightly over the roof, but not so tightly that you tear it. Nail it securely at that point. You can adjust the distance slightly if you are close to a rafter, since it is better to nail directly into a rafter if you can. Repeat the process across the entire roof.

6.)Start the next row of insulation just above the first row, allowing a few inches of overlap. Follow the same procedure to attach this row of insulation, and do the same for each subsequent row until you reach the peak of the roof.

7.)Place roof closure strips along the eaves on both sides of your roof. These keep wind and rain out, keeping the temperature insistent and protecting the insulation. Make sure the strips you use match the design of your metal panels. Your roof is now insulated and ready for placement of the corrugated metal panels.