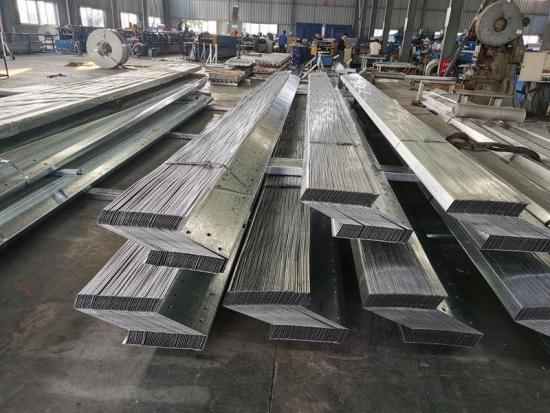

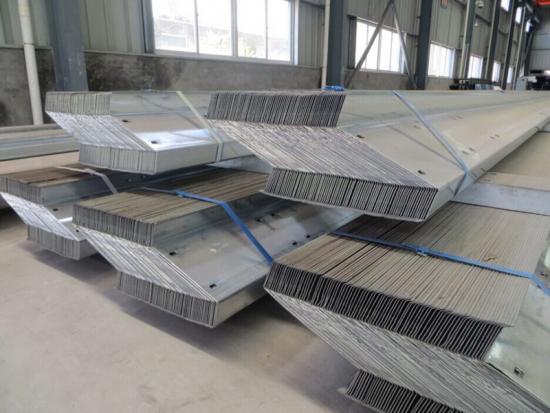

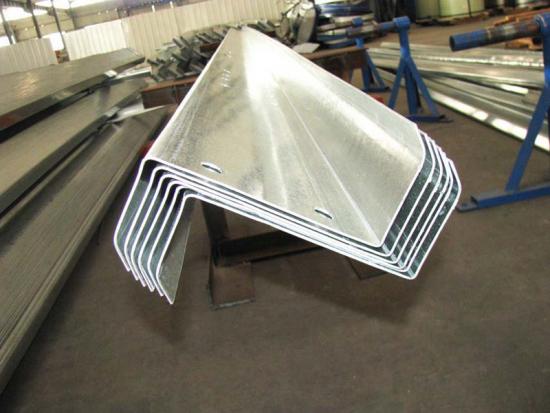

Steel purlin is usually made of cold-formed steel that is thin enough to put screws through. Cold-formed steel is made by rolling or pressing thin sheets of steel into the desired shape. Usually in "C" shape or "Z" shape. Purlins are most commonly used in Metal Building Systems, where Z-shapes are utilized in a manner that allows flexural continuity between spans.

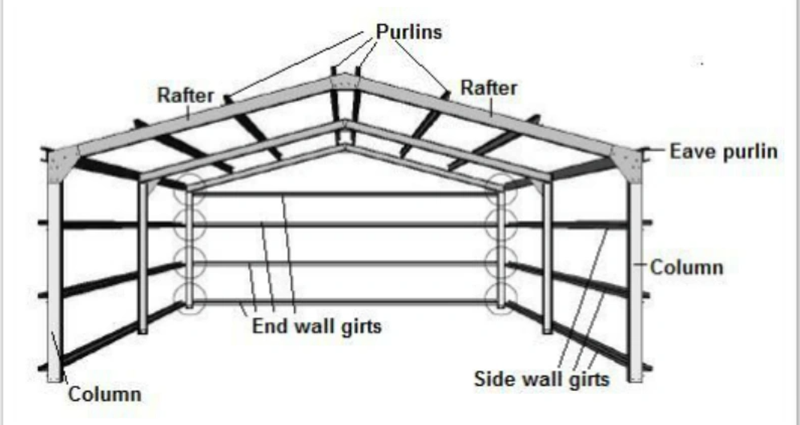

Purlins are secondary steel framing members used for roof and wall support as well as a header, sill, brace, and more.

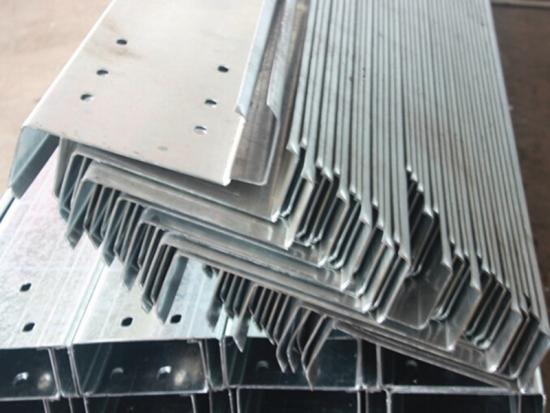

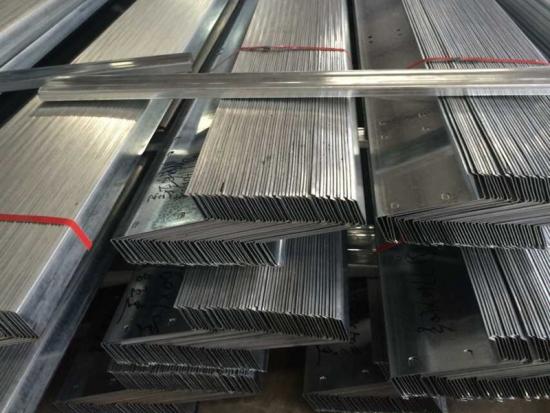

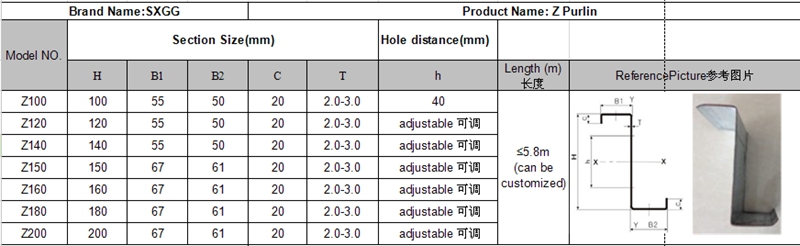

1)Material preparation:Usually our steel material standards of Z purlin is Chinese standards Q195/235/345,we could also make as per your steel standards;

2)Hole pre-punched:If you have hole punching requirement,we could exactly punch the holes as per your requirements;

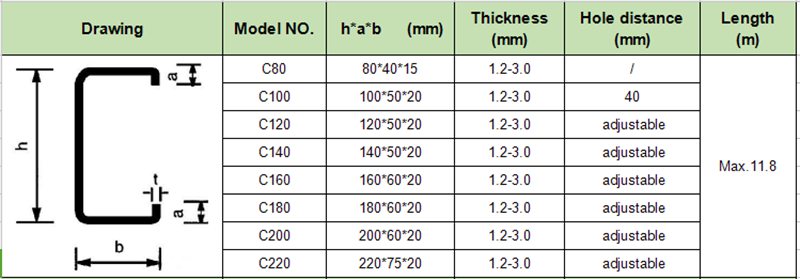

3)Cutting:Length could be any customized size,but it will be limited by container size,it's max 5.8meters for 20FT container and 11.8meters for 40FT container;

4)Quality inspection:We have QC people in workshop to do quality inspection,to ensure the product quality for customers.

It is used widely as purlin and wall beam on steel structure construction. Also it can be combined into a light weight roof truss, brackets, etc. In machinery light manufacturing, C purlin can also be made into Column, beam or arm limb, etc.