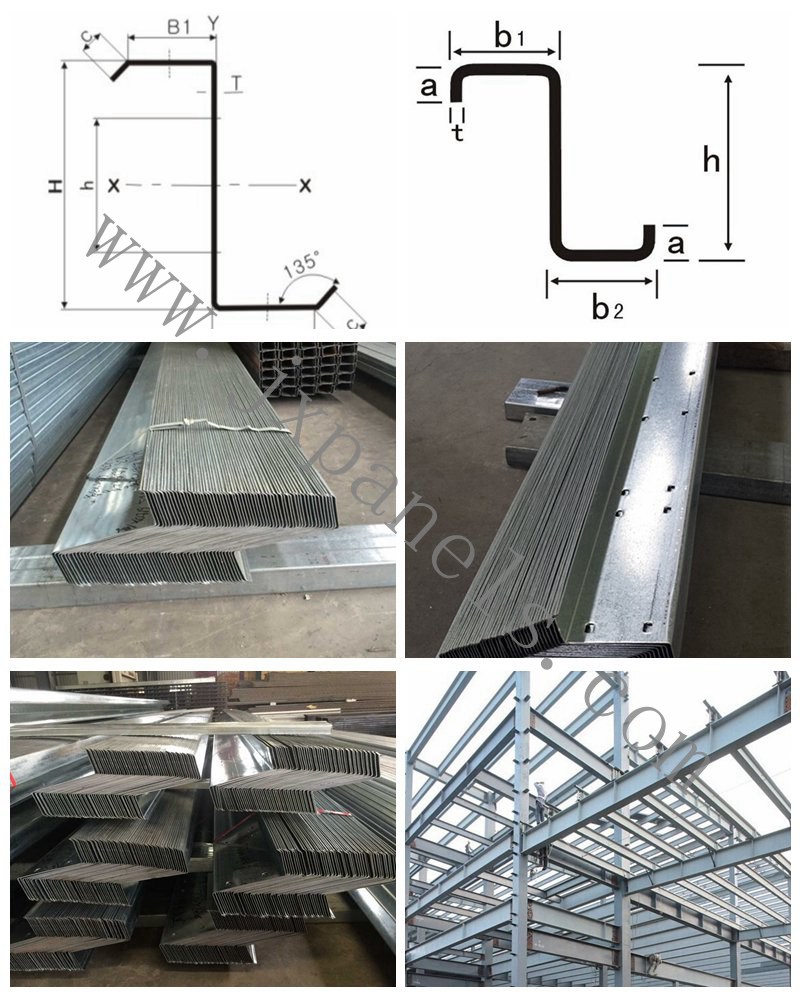

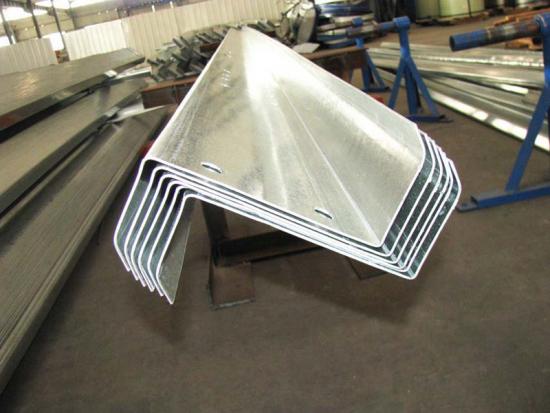

Steel purlin is usually made of cold-formed steel that is thin enough to put screws through. Cold-formed steel is made by rolling or pressing thin sheets of steel into the desired shape. Usually in "C" shape or "Z" shape. Purlins are most commonly used in Metal Building Systems, where Z-shapes are utilized in a manner that allows flexural continuity between spans.

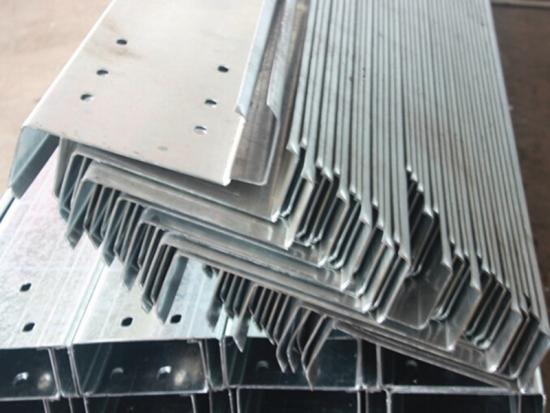

Purlins are secondary steel framing members used for roof and wall support as well as a header, sill, brace, and more.

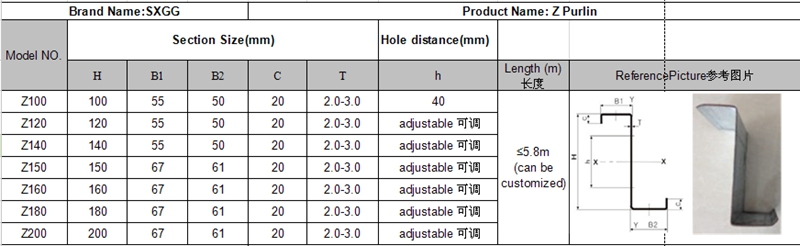

Z purlins: Z steel purlin is made of hot rolling steel sheet,and strictly under the cold roll formed by machine.,which is using as steel building purlins.Compare to the traditional box iron,Z section purlins can save 30%material wastage,and it has thin wall,light weight,good section performance and high strength features.Compare to C purlins,Z purlins are specially used for large slope roof.

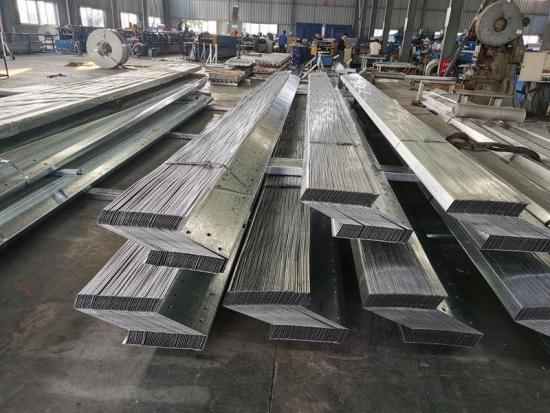

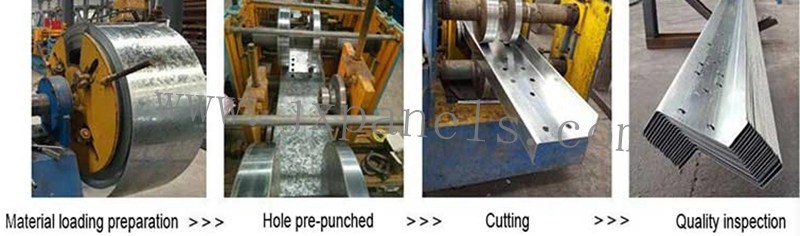

Pre-punching service of Z steel frame:

In order to make construction on-site faster and easier,steel Z purlins could be pre-punched in our factory.

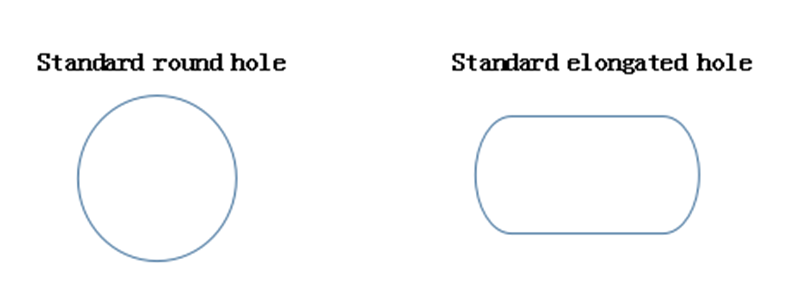

There is two kinds of holes we have,as per Chinese GB standards,round holes and elongated holes.which is as per the following picture showing:

Holes are made during production at continuous line,some additional notes are showing as follows:

Holes can be made in a row or positions as per your design;

Oval and rectangular holes can be rotated by 90°;

Please contact us for additional information about the pre-punching possibilities,if you have any special hole punching requirement about hole size and hole shapes.

Z Purlin - The zed or Z purlin is shaped like a letter Z. Its shape allows the purlin to overlap with others at the joints. This gives zed purlins the potential to be much stronger than C purlins. Z Purlins are mainly used in walls or for large roofing projects.