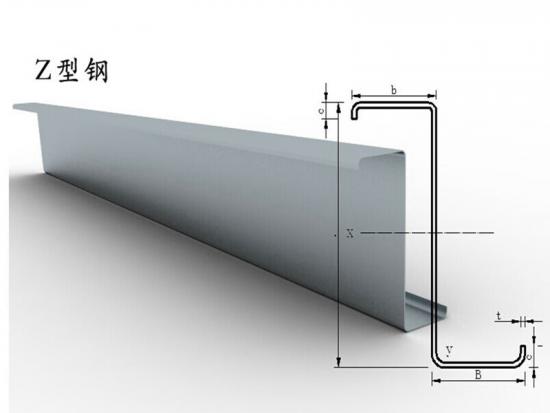

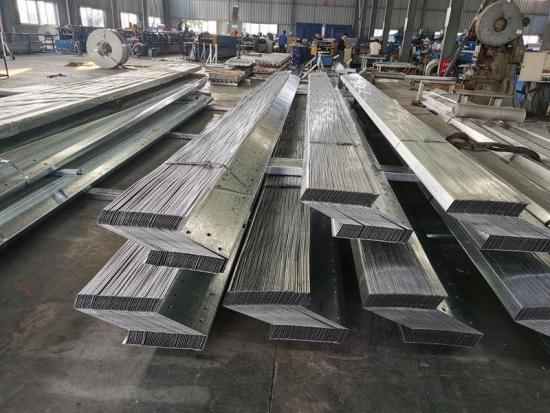

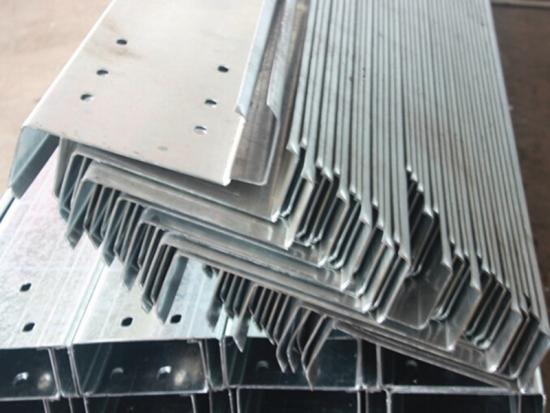

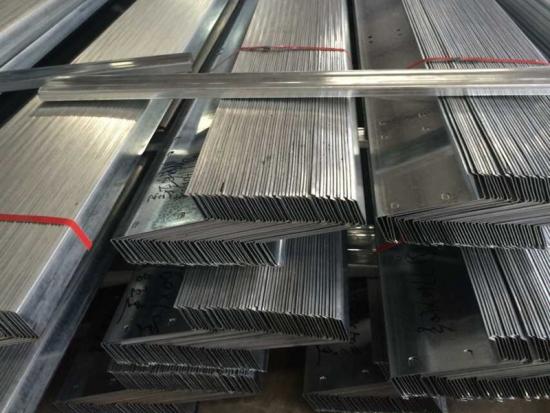

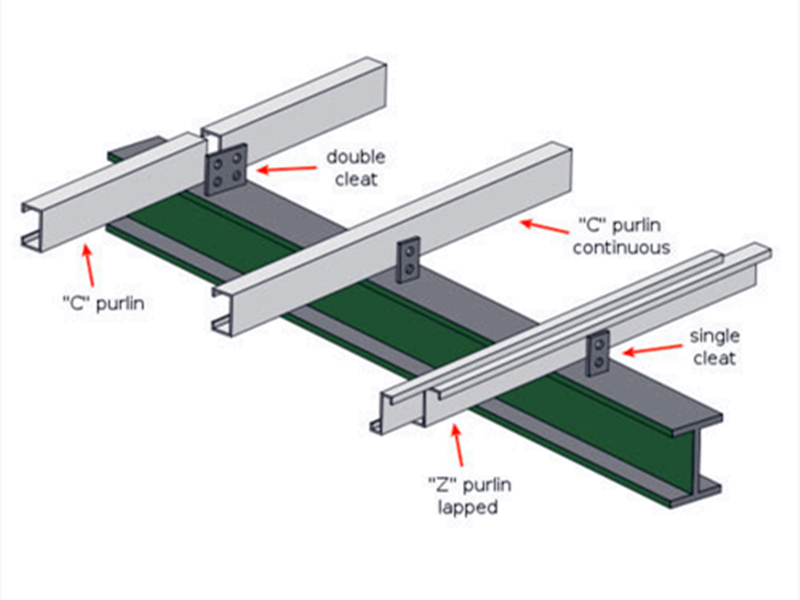

Steel purlin is usually made of cold-formed steel that is thin enough to put screws through. Cold-formed steel is made by rolling or pressing thin sheets of steel into the desired shape. Usually in "C" shape or "Z" shape. Purlins are most commonly used in Metal Building Systems, where Z-shapes are utilized in a manner that allows flexural continuity between spans.

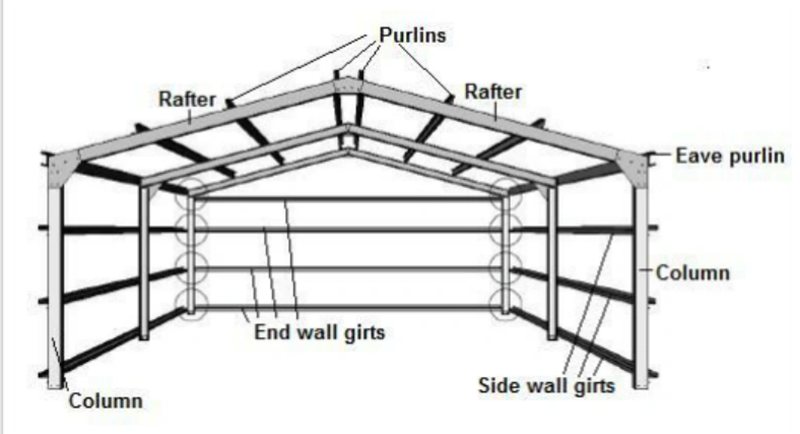

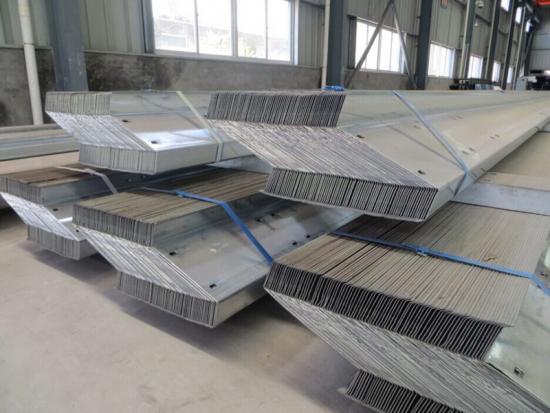

Purlins are secondary steel framing members used for roof and wall support as well as a header, sill, brace, and more.

Purlins constitute the most important aspect when it comes to any kind of structural support system in a building. It's a horizontal beam used for structural support, most commonly applied beneath roofs. They attain support from the rafters and building walls. Purlin manufacturers most commonly produce three types of purlins, namely, Z and C purlins and rectangular hollow section purlin.

Purlin Roofing Systems

Designed to reduce the distance the rafters have to span, metal purlins support the loads from the roof deck and help to prevent the roof from sagging. Metal for Roofing offers two types of galvanized purlins:

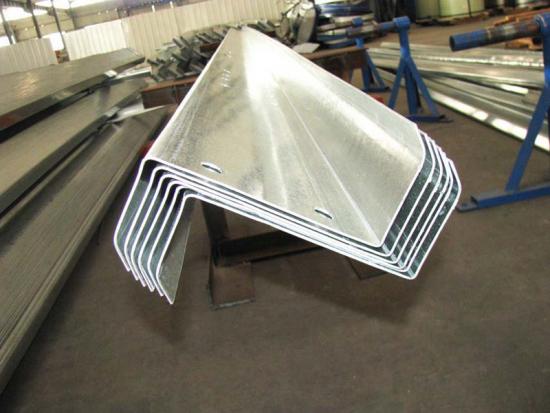

C Purlin - Cee or C purlins are shaped like a squared-off letter C. They are often used for structural support in walls and as floor joists in addition to roofs.

Z Purlin - The zed or Z purlin is shaped like a letter Z. Its shape allows the purlin to overlap with others at the joints. This gives zed purlins the potential to be much stronger than C purlins. Z Purlins are mainly used in walls or for large roofing projects.

Advantages of C Purlins

Ability to span length

Purlin construction is easier to assemble and handle

Assured dimensions and straightness

High durability, versatility and uniform quality

Low transportation cost due to decreased weight