Floor Decking Steel Sheet is roll formed by roll forming machine, mainly using galvanized steel, at thickness 0.8 mm ~ 1.2mm. Simple shape with high rib and high strength. Put the panel above the welded wire net, fill cement between them. This panel is usually used as the floor of high buildings, it can save steel mound and can also save the weight, in the same loading capacity, use this panel, and save the steel quantity, and thus save cost.

Floor decking steel sheet is mainly using galvanized steel, at thickness 0.8 mm ~1.6mm; Simple shape with high rib and high strength. Put the panel above the welded wire net, fill cement between them.

This panel is usually used as the floor of high buildings, it can save steel mound and can also save the weight, in the same loading capacity, use this panel, and save the steel quantity, and thus save cost.

Advantages of composite floor steel decking:

|

(1) |

light in weight, high intensity, huge lodging capacity as well as good anti-earthquake capability |

|

(2) |

simple in construction operation, easy to install |

|

(3) |

reducing the cost of raw material |

|

(4) |

enable easy operation wiring, and so on |

|

2. Raw materials of composite floor steel decking: |

|

|

(1) |

Hot dipped galvanized steel sheet Q235 Q345 |

|

(2) |

Galvalume steel sheet(Zinc- aluminum galvanized steel sheet) |

|

(3) |

Aluminum sheet |

|

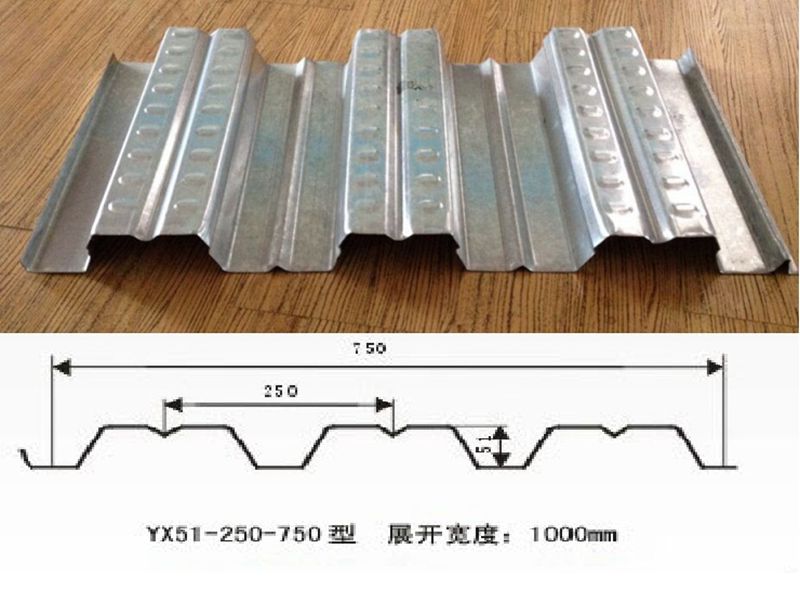

3. specification of composite floor steel decking: |

|

|

Thickness |

0.8-1.2mm; max 1.6mm |

|

Width |

600mm-1025mm (depend on the model you chose) |

|

Length |

0mm-11800mm |

|

Model |

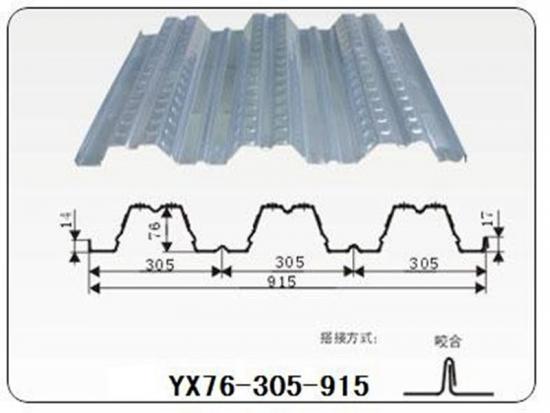

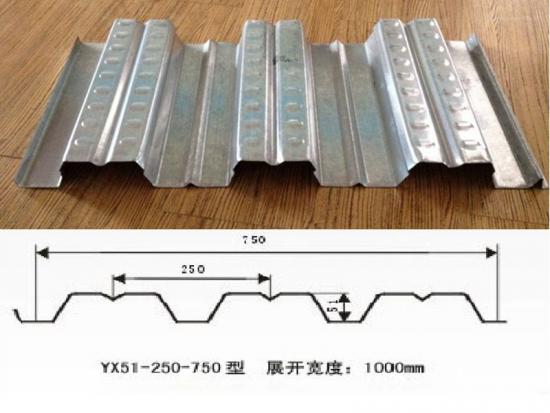

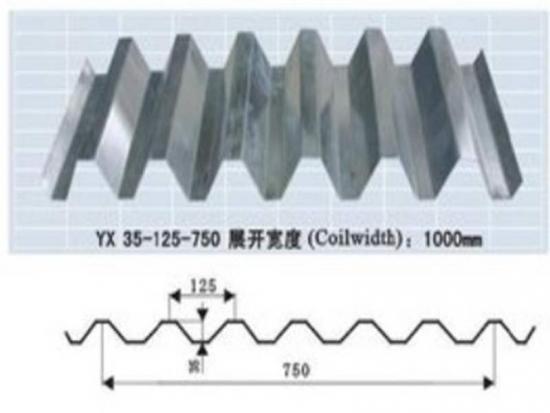

YX76-305-915/ /YX35-125-750/YX130-280-600//YX76-313-940 |

|

Certification |

JIS/ASTM/GB/T12755-2000 |

|

Thickness Tolerance: |

+/-0.04mm |

|

Width Tolerance: |

+/-5mm |

|

Zinc Coating: |

60-275g/m2; max 350g/sqm |