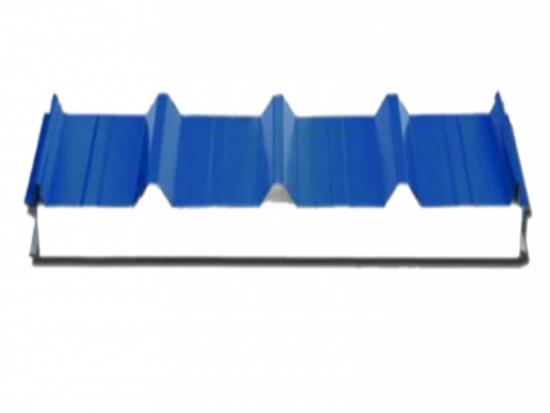

PU sandwich panel is the top grade new building material with thermal insulation, load-bearing, fireproof, low thermal conductivity, easy installation, rich colors, beautiful appearance and etc.Therefore they are widely used in large industrial plants, large-sized factory buildings, warehouses, cold storage, exhibition halls, kiosks, gymnasiums, etc.

| PUR/PIR Sandwich Panel Technology Data | |

| Density | 40-45kg/m3 |

| Thermal conductivity | 0.019-0.023W/M.K |

| Moisture permeability coefficient | ≤3.34Ng/Pa/m.s |

| Water absorption | ≤0.5g/100cm2 |

| Enclosed rate | ≥97% |

| The compression strength | ≥220KPa |

| The bending strength | ≥2450KN/m2 |

| Oxygen index | ≥28 |

| Fire proof | B1 |

| Dimensional stability | ≤1% |

| Application temperature | -50ºC-150ºC |

| Exterior Steel thickness | 0.4-0.7mm |

| Interior steel thickness | 0.4-0.7mm |

| Core material thickness | 40/50/60/75/100/120/150/200mm |

| Length | Less than 11.8m |

| Effective width | Wall panel:400-1120mm;Roof panel:1000mm |

| Grace finish | Embossment,small wave,big rib,flat finish |

| USAGE |

Roof and Wall |

| Advantage |

Heat Insulation, light weight, quick installation,waterproof, fireproof, soundproof, energy-saving,environmental friend

|

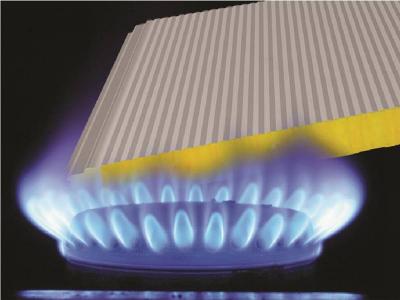

The rigid polyurethane foam core provides excellent thermal insulation for buildings.

This comes from the excellent thermal conductivity coefficient, λ = 0.022, unparalleled by any mineral wool or EPS sandwich panel. The concealed fasteners mean just that: the joints between the panels are hidden from sight, which improves the aesthetic value of the result.

Besides the superb solidity and durability with a beautiful appearance, the hard polyurethane resin foam used for panels performs quite well in heat insulation.

In times of high energy costs, roof panels with a highly heat-insulating core of polyurethane rigid foam are the first choice. With two layers of hot-dip galvanised and plastic-coated sheet steel and the PU insulating core, this roof panels also meet the highest standards in moisture protection. Additional benefits which stand out are high rigidity and load capacity allowing more distance between supports. In addition, the combination of long panel lengths and low weight facilitates economic construction. Convincing arguments: simple and quick assembly outstanding thermal insulation triple sealing system easy assembly connection principle module width 1,000 mm wide beam and support spacing panel lengths up to 24,000 mm.