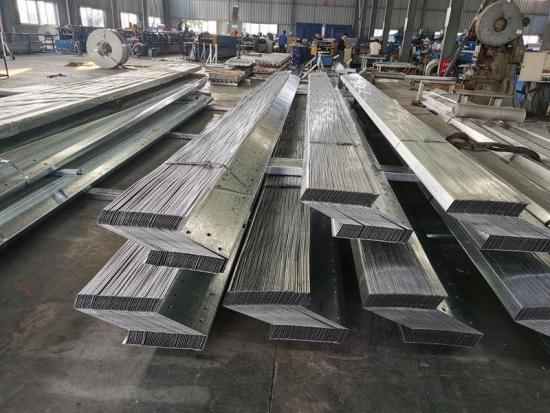

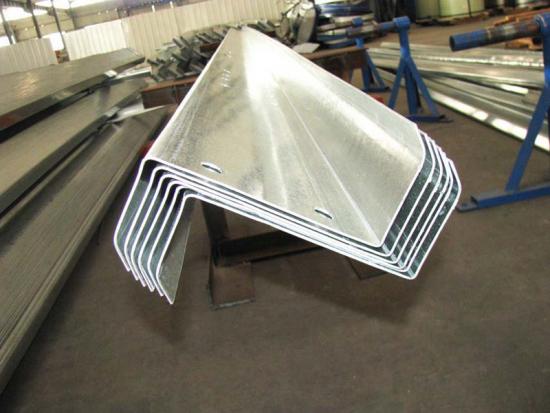

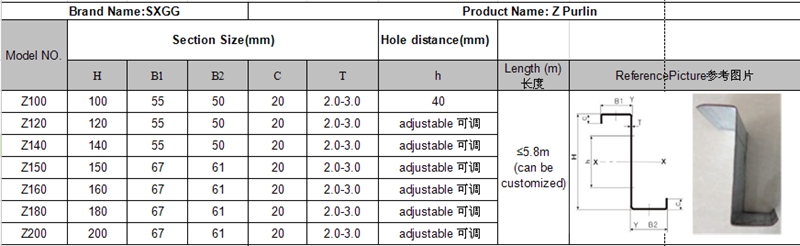

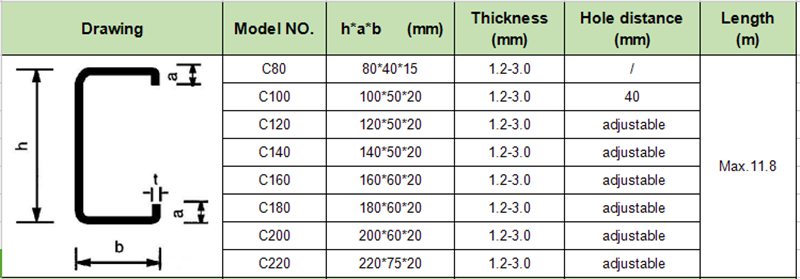

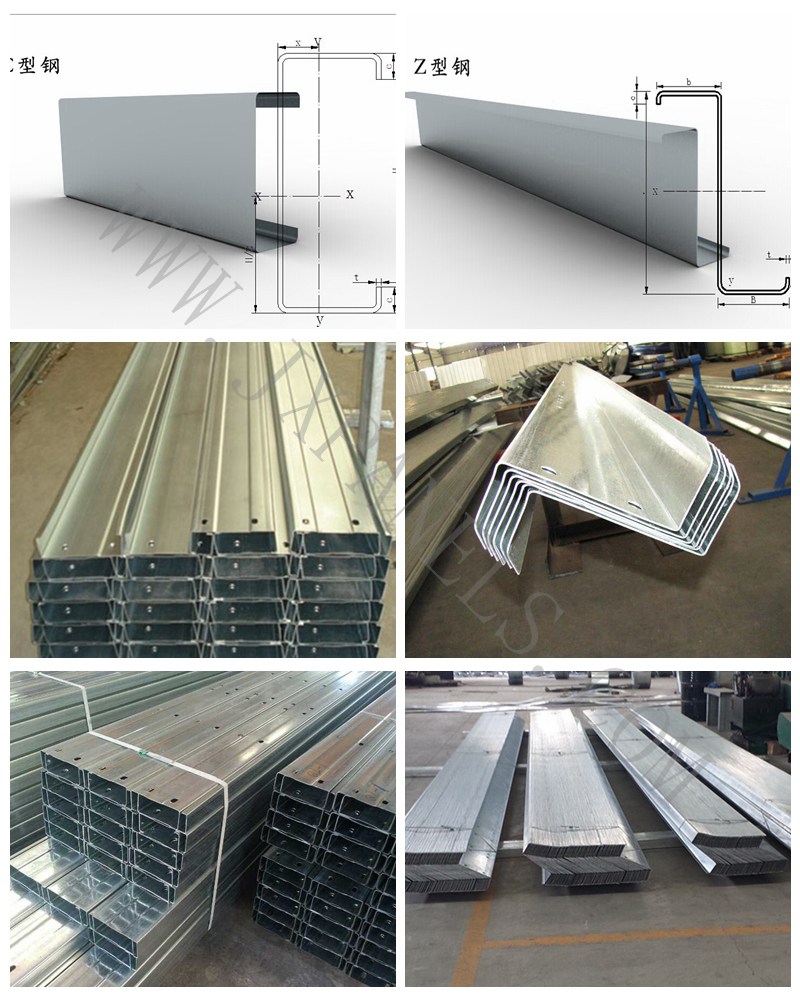

Steel purlin is usually made of cold-formed steel that is thin enough to put screws through. Cold-formed steel is made by rolling or pressing thin sheets of steel into the desired shape. Usually in "C" shape or "Z" shape. Purlins are most commonly used in Metal Building Systems, where Z-shapes are utilized in a manner that allows flexural continuity between spans.

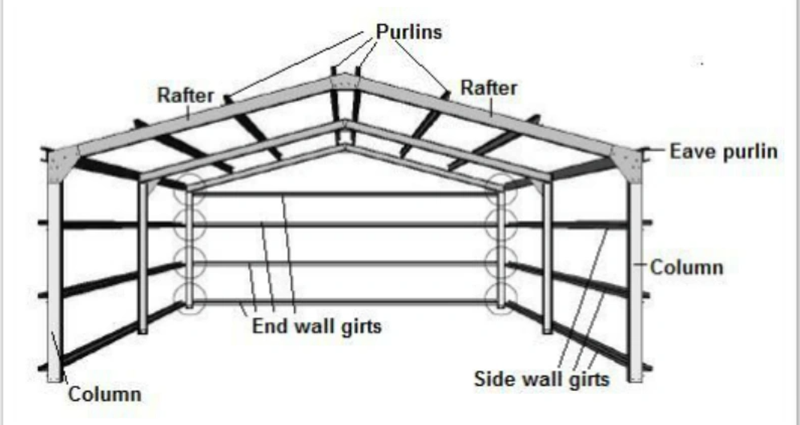

Purlins are secondary steel framing members used for roof and wall support as well as a header, sill, brace, and more.

We manufacture a complete range of structural C and Z purlins and girts for industrial buildings, garages, verandahs, and carports, in fact anywhere that strong, reliable steel framing is required. Manufactured from quality galvanised steel, this is a fully integrated system allowing for flexible design options.

Supplied plain or punched, galvanised purlins are manufactured from high tensile steel for increased strength, reduced weight, and a long serviceable life.

Note:If customized Zee purlins size is required,please don't be hesitated to contact with us and let us know the size details.Our production team will check and see if we could meet your demand on the special size.

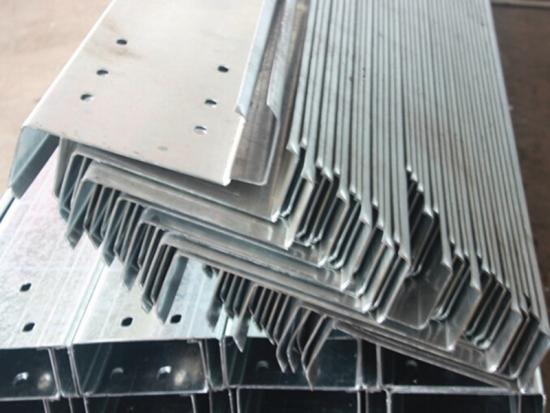

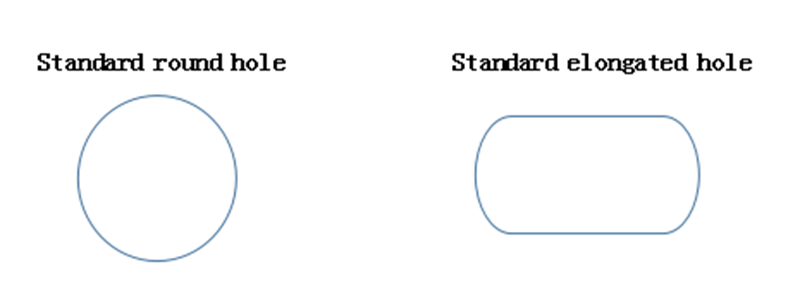

Pre-punching service of Z steel frame:

Pre-punching service of Z steel frame:

In order to make construction on-site faster and easier,steel Z purlins could be pre-punched in our factory.

There is two kinds of holes we have,as per Chinese GB standards,round holes and elongated holes.which is as per the following picture showing:

Holes are made during production at continuous line,some additional notes are showing as follows:

Holes can be made in a row or positions as per your design;

Oval and rectangular holes can be rotated by 90°;

Please contact us for additional information about the pre-punching possibilities,if you have any special hole punching requirement about hole size and hole shapes.

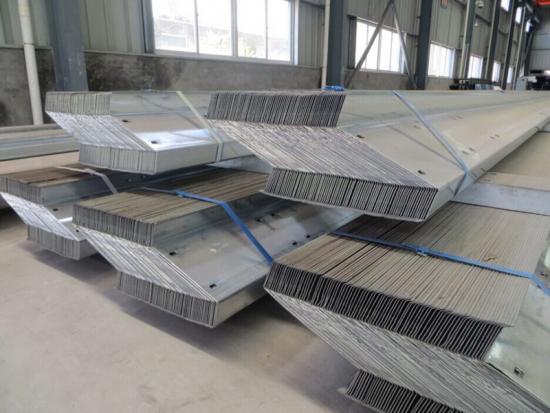

Ability to span length

Purlin construction is easier to assemble and handle

Assured dimensions and straightness

High durability, versatility and uniform quality

Low transportation cost due to decreased weight