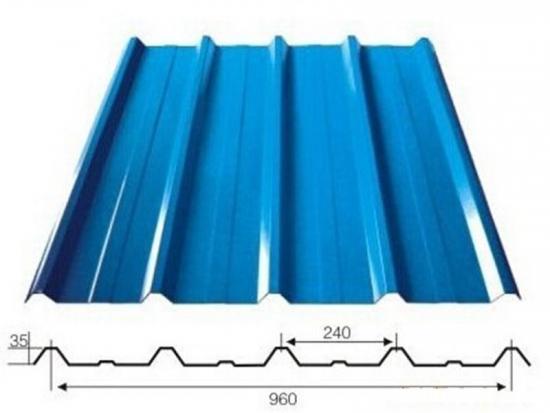

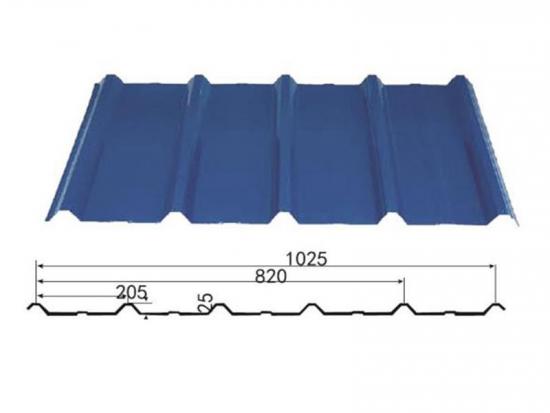

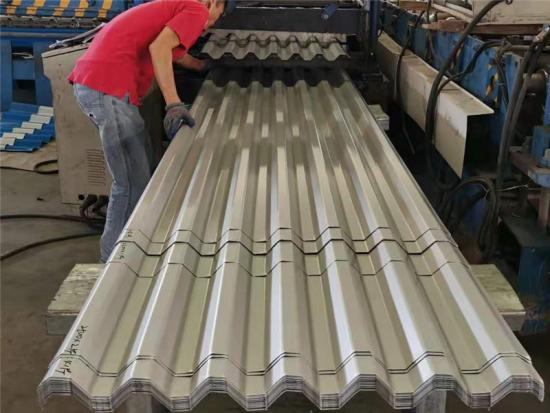

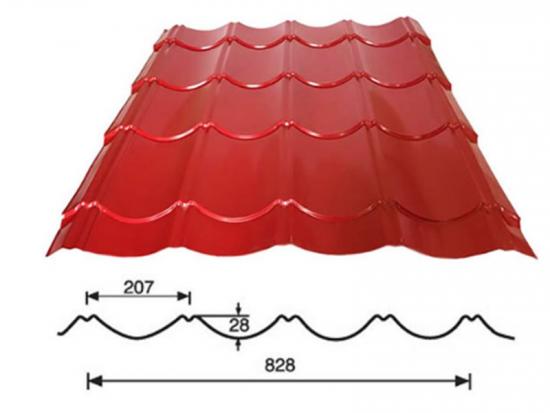

The corrugated steel sheet is made by cold-rolled steel plate, electro-galvanized steel plate, hot-dip galvanized steel plate or galvanized steel plate as substrate after surface degreasing, phosphating, chromate treatment, and coated with organic coating. .

The common coatings for corrugated steel sheets are polyester (BHP XRW coating system, Baosteel JZ, Korea PGS, Taiwan PE), by silicon resin (PSS), fluororesin (PVDF), etc. The thickness of the coating is generally 20-25μ on the surface and 8-10μ on the back. Color coated steel sheets are generally quoted as ASTM A527 (galvanized), ASTM AT92 (aluminum galvanized), JIS G3302 in Japan, EN/0142 in Europe, KS D3506 in Korea, Q/BQB420 in Baosteel. These sheets can be used as roofing of the buildings, some sheets with low rib height can be used for wall cladding.

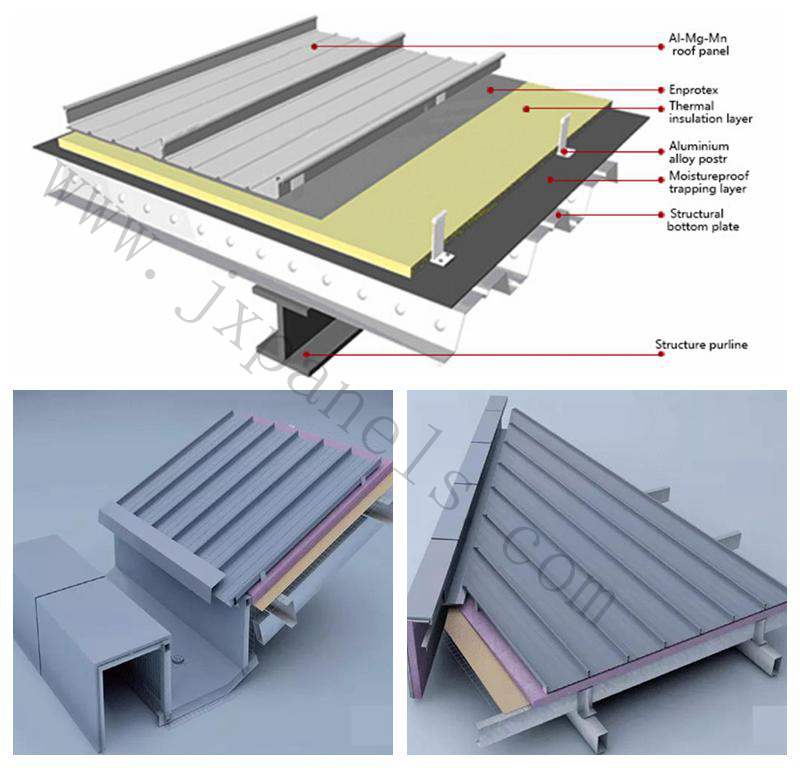

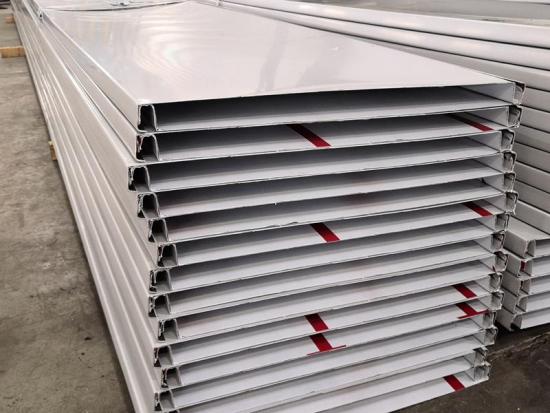

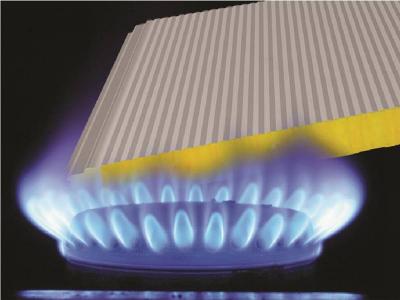

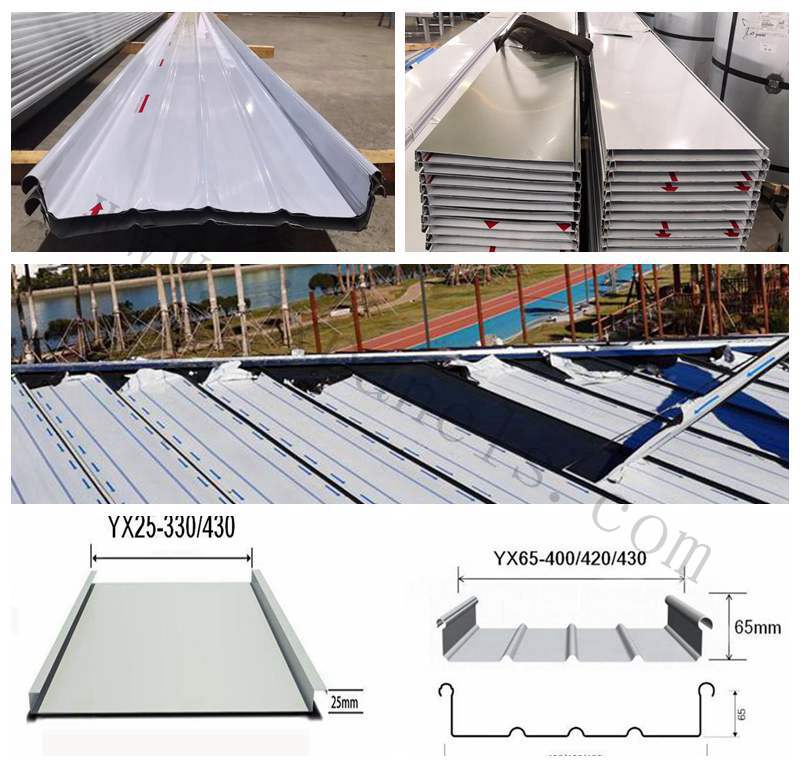

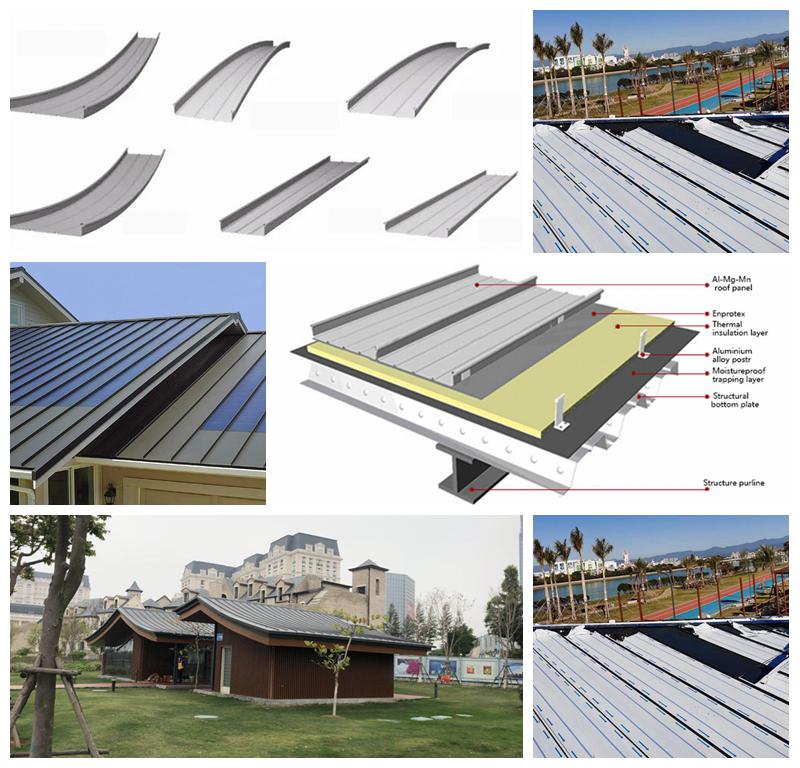

AL-Mg-Mn Alloy Sheet Standing seam roofing sheet (hereafter called Al-Mg-Mn alloy plate) is a new kind of roofing plate,which is widely used in modern construction industry. As the Al-Mg-Mn alloy moderates structure strength, weather fastness, stain-resistant, easy to bend welding process etc., it is widely recognized as a design life of more than 50 years of roofing and wall materials, and it plays an important role in the development of modern architecture to the comfortable, light-weight, durable, economic, environmental protecting and other parties.

In construction industry, the aluminum alloy is mainly used for extruded profiles and rolling. It's elongation, hardness, tensile strength,yield strength and other indicators are suitable for roof curling, rolling and the processing of processing equipment. Therefore, it's widely used in roofing, wall system of outdoor building maintenance project. With a variety of painting systems and coating processes, the appearance is colorful.