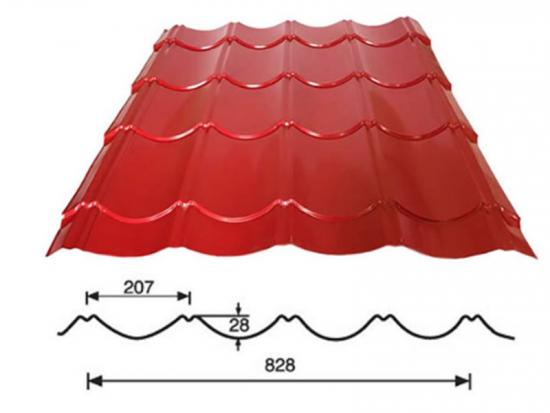

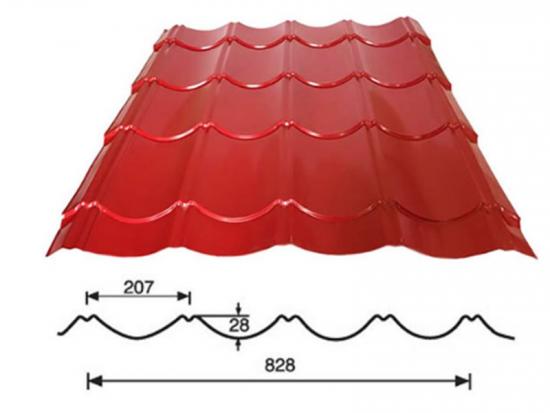

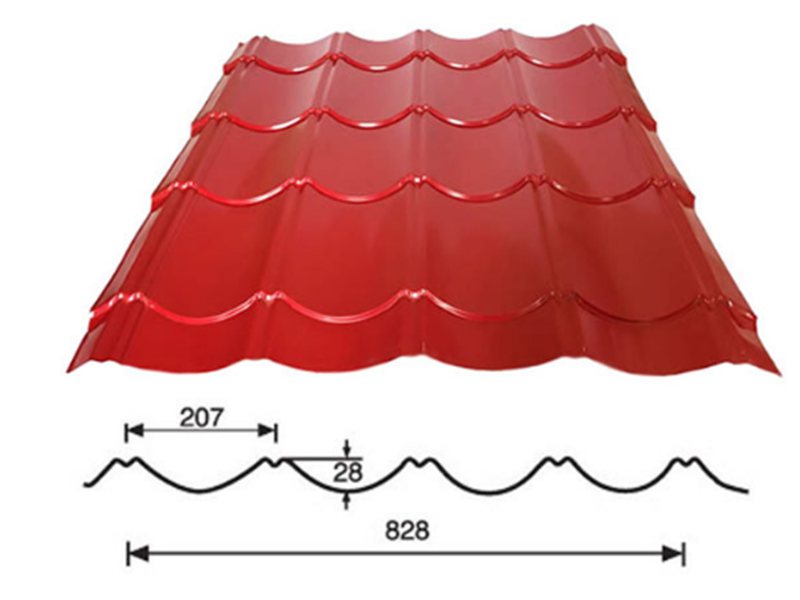

YX28-207-828 is popularly used in steel villas,summer houses,etc.This kind of steel roofing sheets has a retro and elegant appearance, so it is favored by both domestic and foreign customers, and the roof cladding type is made of steel, which ensures its reliability and strength.

|

Model NO. |

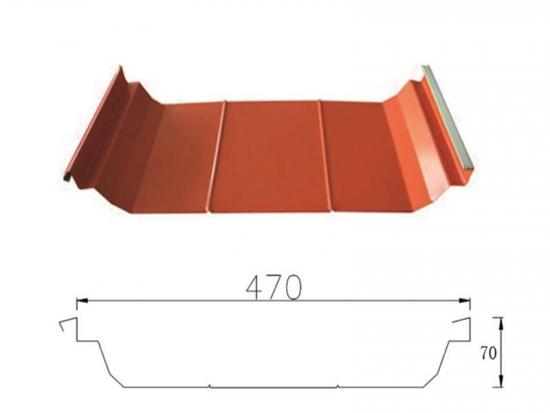

YX28-207-828 |

|

Modular width |

828 mm |

|

Feeding width |

1000 mm |

|

Available thickness |

0.3 - 0.6 mm |

|

Length |

Limited length to 20FT container: 5.85 meters; Limited length to 40FT container: 11.85 meters; |

|

Coating type |

PE, SMP,PVDF, HDP, etc. |

○ The appearance of this kind of roofing sheets is elegant,which makes the building more design sense;

○ Ultra-long and ultra-wide tile type, reduce the overlap, and prevent hidden dangers of water leakage;

○ Light weight, high strength and durability;

○ A variety of colors for choices;

○ Installation is quick and easy.

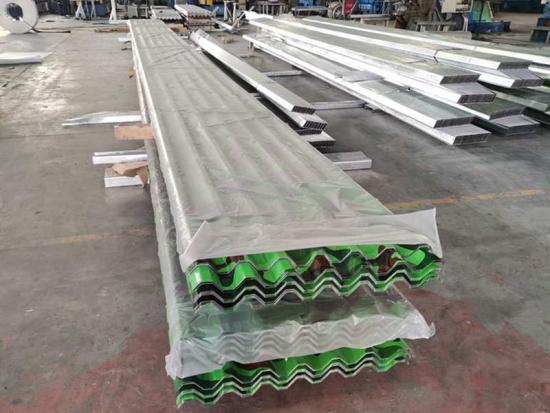

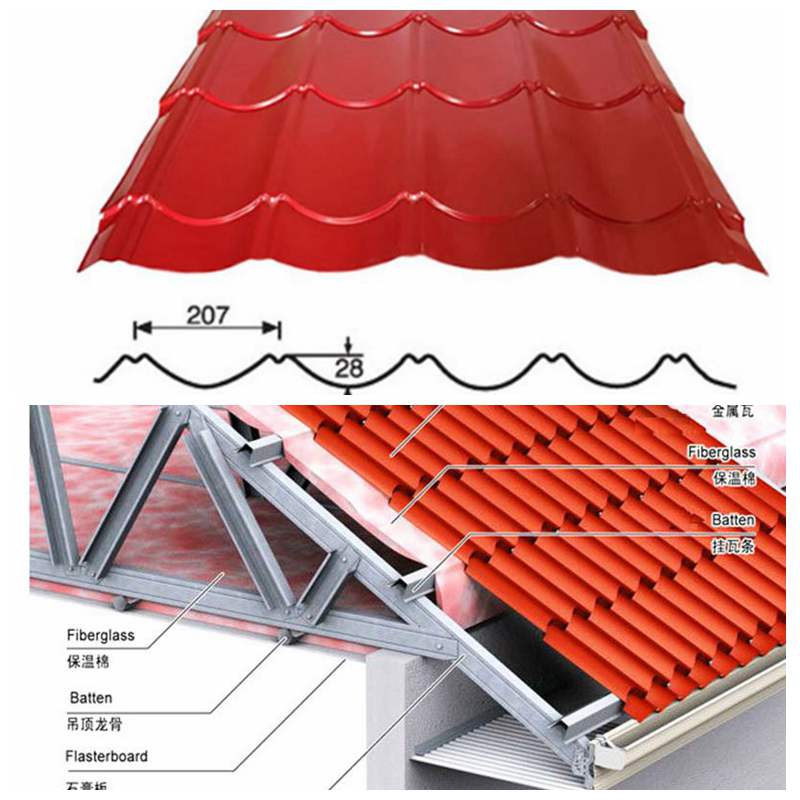

7.Roofing metal sheets installation way for reference:

Unloading for roof panels:

Unloading for roof panels:

) There are two fixing methods for color steel plate installation, which are penetrating type and concealed type:

Penetration is the most common method of installing roof and wall color steel. Self-tapping screws or rivets are used to secure the color steel plate to a support member such as a stringer. Penetration type penetration fixation is divided into wave peak fixation, trough fixation, or a combination of the two. Concealed concealed fixing is a method of fixing the special concealed buckle with the dark button type color plate to the support member (such as the purlin), and the fixing method of the female rib of the color plate and the central rib of the concealed button is generally used for the house. Panel installation.

2) The lateral and end overlap of the color steel plate:

When installing each steel plate, it should be placed on the front steel plate accurately and clamped to the previous steel plate until both ends of the steel plate are fixed. A simple and effective method is to use a pair of jaw clamps to clamp the overlapped steel plates. When the steel plate is placed in the longitudinal direction, the end portion, especially the upper end portion, needs to be clamped with the gusset portion, so that one end of the steel plate can be seated, and the overlap at one end is also in the correct position, thereby fixing the steel plate. During the fixing process, the clamp should always clamp the steel plate in the longitudinal direction. Before installing the next steel plate, each steel plate must be completely fixed. The fixing must start at the center of the steel plate and then extend to both sides, and finally the lap joint of the steel plate is fixed. For end lap joints, since the roof and wall profile panels are made by continuous processing, the steel plates can be supplied at a length limited by the transport conditions, usually without overlapping, and the length of the steel plates is sufficient to meet the needs of roofing.

3) Selection of self-tapping screws:

When selecting a set screw, the fixed part should be selected according to the service life of the structure, paying particular attention to whether the life of the case material is consistent with the life of the specified fixed part. Also note that the thickness of the steel string cannot exceed the self-drilling capability of the screw. Screws are currently available in plastic heads, stainless steel top covers or special durable finishes. In addition, in addition to the screws that secure the fasteners, the other screws are provided with waterproof gaskets and are provided with special gaskets for the lighting panels and under special wind pressure conditions.

4) The details are especially important:

For roof color steel, color steel plates should be trimmed on the eaves and eaves to prevent rainwater from entering the roof more effectively. When the roof panel is on the ridge, the edge between the ribs of the steel plate can be folded up with a hemming tool. It applies to all upper ends of all 1/2 (250) roof steels to ensure that water blown by the wind or under the deck does not flow into the building.

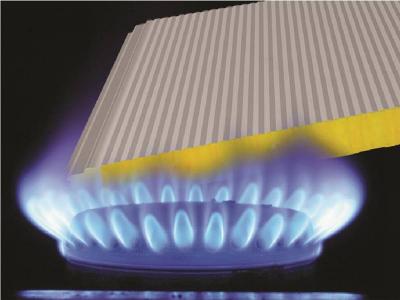

5) The insulation should be placed in a hot place:

In the southern color steel plate is generally designed as a single layer, in order to reduce solar radiation heat into the interior of the building, when installing the roof panel, the roofing system can be installed with insulation. There is a very simple, economical and effective way to apply a double-sided reflective foil film to the stringers or slats before installing the roofing colour steel plate. This method can also be used as a steam barrier to reduce agglomeration. If the film is allowed to sag between the supports by 50 to 75 mm, the air layer between the film and the roof panel will further enhance the heat insulation effect.